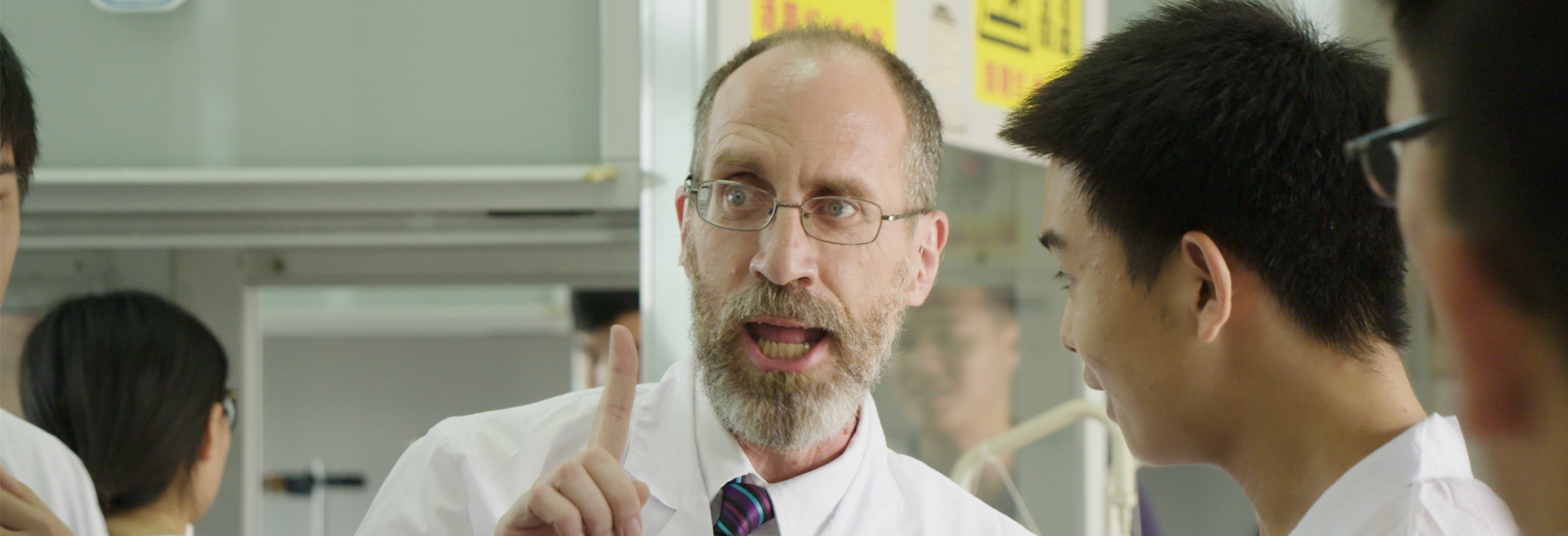

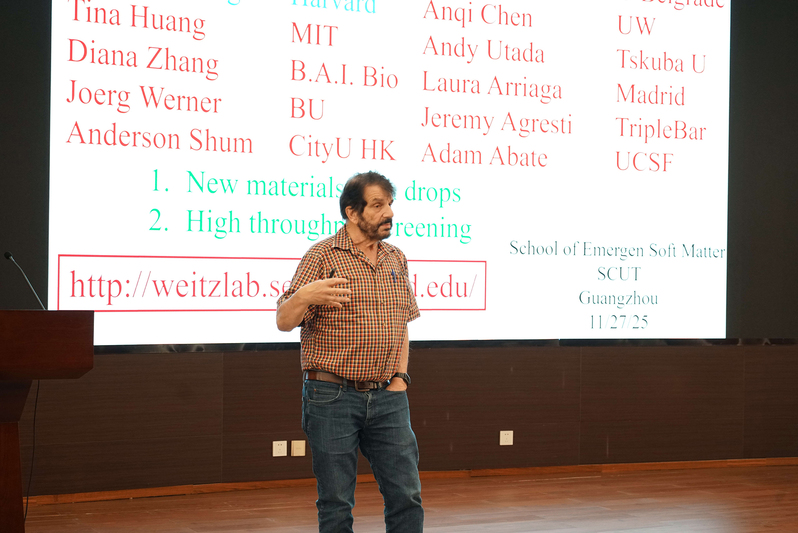

On the afternoon of November 27th, the School of Emergent Soft Matter invited Professor David A. WEITZ, a member of the American Academy of Sciences, the American Academy of Engineering, the American Academy of Arts and Science, and a professor at Harvard University, to give a talk for the Academician Lecture Hall, on the cutting-edge progress of microfluidic technology in materials science, drug delivery, enzyme engineering, and other fields under the title Microfluidic Technology: From Basic Innovation to Industrial Revolution.

Microfluidic basic innovation: high throughput, low consumption, precision control

Professor Weitz introduced the glass capillary microfluidic platforms developed by his team. The device can be quickly constructed in about 30 minutes and can achieve stable generation of over 1000 droplets per second, with a droplet size variation coefficient of only 1-3%. Compared to traditional micro reaction systems, the consumption of reagents has been reduced by 8 orders of magnitude, greatly improving experimental efficiency and reproducibility. This series of fundamental innovations provides a high-precision and high-throughput technological foundation for fields such as material processing, drug loading, and cell engineering.

Intelligent delivery system: from polymer vesicles to membrane asymmetric liposomes

Based on a high-precision droplet control platform, the Weitz team has developed three representative intelligent delivery systems: one is thermosensitive polymer vesicles, which can achieve precise drug release through phase change response; The second is the pH responsive intestinal targeting system, which can release active ingredients in specific intestinal environments and improve oral delivery efficiency; The third is membrane asymmetric liposomes, which can be used for the delivery of nucleic acid drugs. The cell transfection efficiency of its mRNA/CRISPR delivery system can exceed 80%. These studies provide important technical support for developing new drug carriers and improving the delivery efficiency of bioactive substances.

Breakthrough in Enzyme Engineering: Microfluidic Driven Ultra Large Scale Screening

In the field of enzyme engineering, microfluidic droplet sorting platforms have demonstrated revolutionary advantages. Traditional enzyme screening typically requires about 2 years and a resource investment of $600000, while the droplet sorting system developed by the team can complete screening in 7 hours at a cost as low as $2.5, with a cost reduction of 99.99%. The platform supports gene library screening at a scale of up to 10¹², making large-scale directed evolution feasible and bringing new possibilities for the development of biocatalysts.

Industrialization Acceleration: Cosmetics and Biopharmaceuticals Take the Lead in Landing

Microfluidic technology is accelerating its transfer from laboratory to industrial end: Microfluidic essence products developed in cooperation with AmorePacific have achieved an annual sales volume of more than one million; The non viral delivery system developed in collaboration with CRISPR has met GMP standards, providing a new solution for the safe delivery of nucleic acid drugs. The large-scale application of microfluidics in industries such as cosmetics, drug delivery, and vaccine carriers is gradually taking shape. Facing technological bottlenecks, Professor Weitz proposed a development strategy of dual line advancement: focusing on multiphase system design and biocompatible material development from 2023 to 2025; From 2024 to 2026, the team will advance the validation research of cancer treatment direction and establish an industrial standard system. The team will initiate clinical grade treatment system validation in 2024 and plan to establish an ISO standardized production system by 2025.

Q&A discussion: Error control and amplification production of droplet sorting

In the Q&A discussion, Professor Weitz proposed a solution of dual fluorescence labeling+electric field verification to address the potential issue of false positives in droplet sorting, which can control the error rate below 0.1%. He also pointed out that the current microfluidic platform has the production capacity of clinical grade liposomes, and future industrial scaling up can be combined with microreactor technology to achieve continuous and large-scale production.

This report comprehensively demonstrates the clear path of microfluidic technology from fundamental innovation to industrial implementation, reflecting the enormous potential of microfluidics in interdisciplinary fields such as materials science, biomedicine, and engineering production. The lecture provided important inspiration for the faculty and students of our School to expand their research horizons and explore cross disciplinary cooperation.