GREENPAPER:

Partners

(1) South China University of Technology

(2) Aristotle University of Thessaloniki

(3) Automation Systems Hellas

Workpackage 1. Greenhouse gas emission prediction models

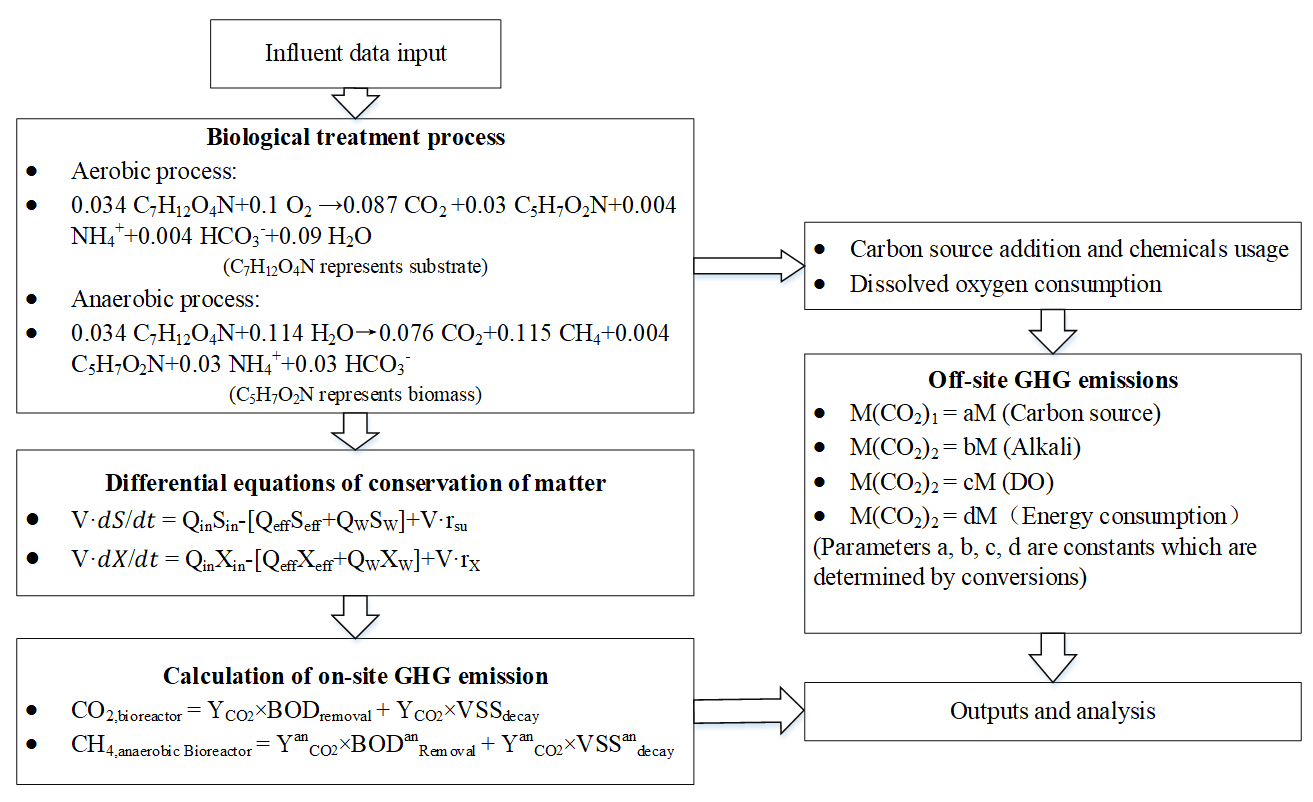

Taking the biological treatment process in papermaking WWTP as the study case, based on the microbial growth kinetics and mass balance this project will develop the emission models of GHG generated from WWTP.

Fig. 1 GHG emission calculation methods

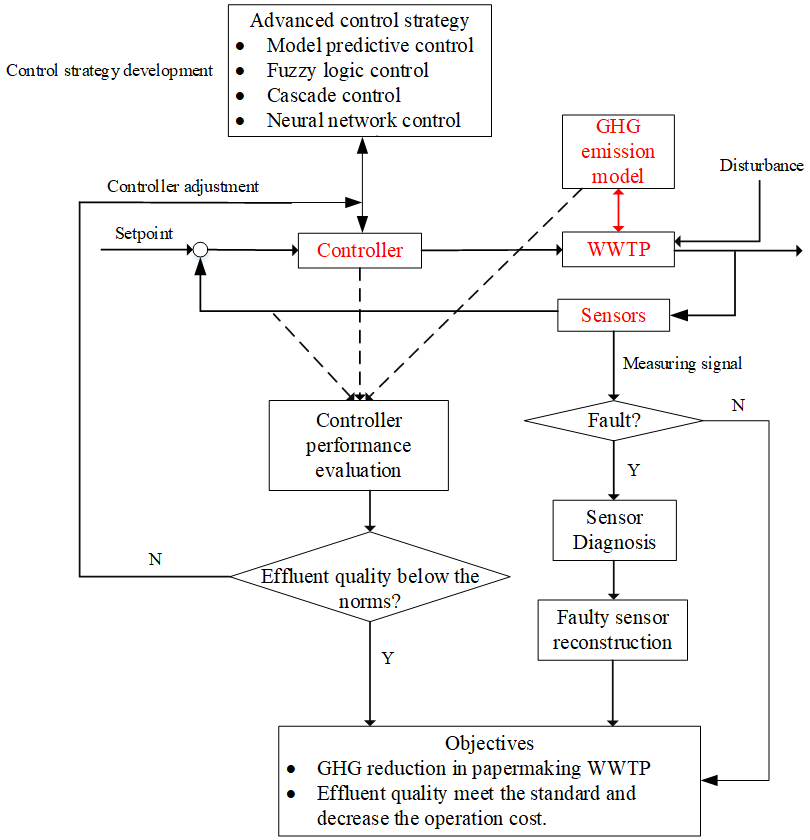

Workpackage 2. Advanced control of papermaking wastewater treatment plant

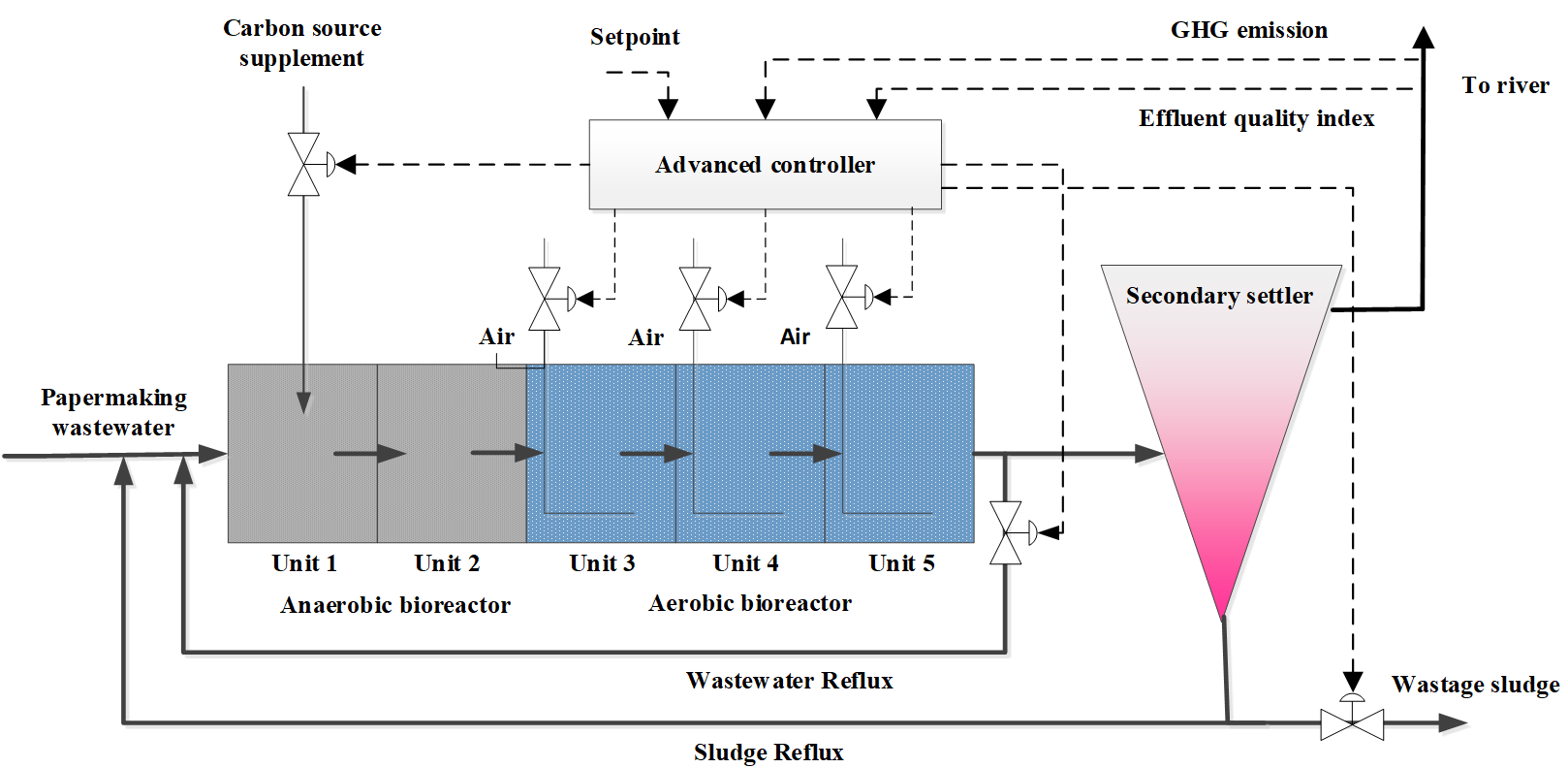

To reduce the GHG emission under the constraints of the required effluent quality, adapting the process operating conditions (such as the aeration rate, wastewater reflux ratio, and wastage sludge) in the papermaking WWTP as the manipulated variables, the multi-objective optimization control strategies will be developed. An accurate but computationally tractable dynamic model of the biological process will be derived along with constraints that ensure the satisfaction of safety, environmental and operational limits. The advanced controller is shown in Figure 2.

Fig. 2 Advanced control framework of GHG reduction in papermaking WWTP

Workpackage 3. Controller performance assessment module

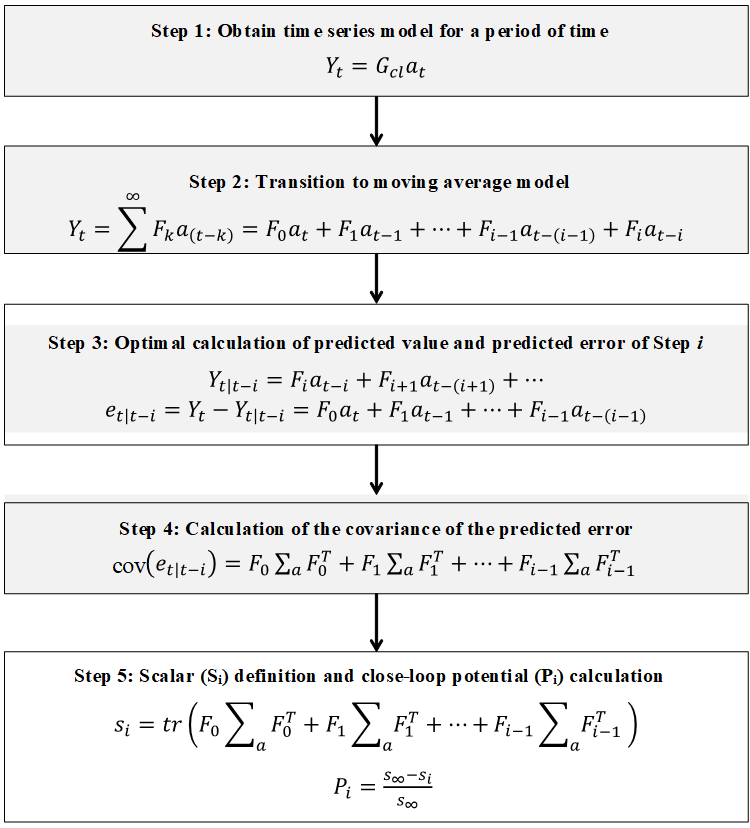

Using the error prediction method and the closed-loop control data of WWTP, the controller performance assess-ment (CPA) module will be investigated. The CPA index of the controller will be used for its performance evaluation and optimization. The calculation procedure of the closed-loop potential of the controller is plotted in Figure 3, where the achieved variability monitored continuously will be compared to achievable targets.

Fig. 3 Calculation procedure of the closed-loop potential for controller

Workpackage 4. Sensor validation module

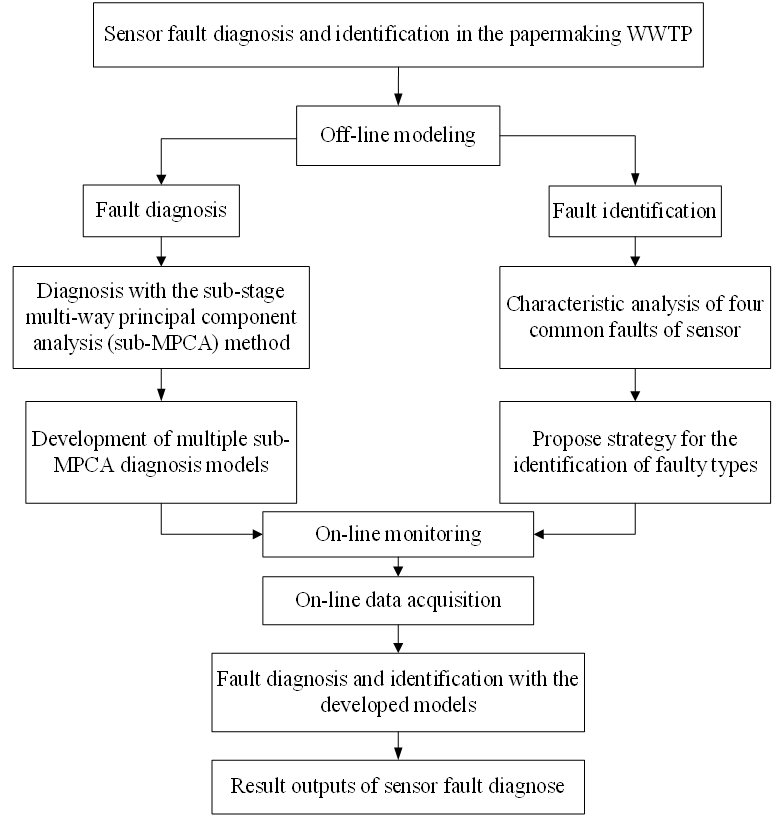

The sensor validation (SV) module will be developed to detect, locate and diagnose the faulty sensors, which means to rate the level of the sensor fault, evaluate its restorability and reconstruct the faulty sensors signal. The Sub-MPCA algorithm and the field data of WWTP in paper mills will be applied to the establishment of the online monitoring and fault diagnosis module. The technical roadmap is indicated in Figure 4.

Fig. 4 Technical roadmap of sensor diagnosis and identification

Workpackage 5. Advanced integrated control framework

To reduce the GHG emission in WWTP under the constraints of required effluent quality for papermaking industry, integrating the GHG emissions model, controller performance assessment and sensors validation modules, an advanced control integrated framework will be developed. Such a framework exceeds the current technology applied in pulp and paper WWTP and is expected to greatly impact the overall performance in terms of GHG emissions and discharged water quality. The outline of the framework is illustrated in Figure 5.

Fig. 5 Advanced control integrated framework for GHG reduction in the WWTP of papermaking industry

Workpackage 6. Project management, dissemination and exploitation

Recent publications:

(1) Huang F., Shen W., Zhang X., Seferlis P., “Impacts of dissolved oxygen control on different greenhouse gas emission sources in wastewater treatment process”, Journal of Cleaner Production, 274, 123233, 2020.

(2) Zhou J., Huang F., Shen W., Liu Zhang, Corriou J-P., Seferlis P. “Sub-period division strategies combined with multiway principle component analysis for fault diagnosis on sequence batch reactor of wastewater treatment process in paper mill”, Process Safety and Environmental Protection, 146, 9-19, 2021.

(3) Gkionis M., Papadopoulos A.I., Shen W., Seferlis P., “Development of a Nonlinear Model Predictive Controller of Flexible Structure for Greenhouse Gas Emissions Minimisation in Pulp and Paper Wastewater Treatment Processes”, Chemical Engineering Transactions, to appear 2021.

Conference proceedings:

(1) Shen W, Huang F, Zhang X, Seferlis P., “Modeling of greenhouse gas emissions during wastewater treatment process and the preliminary study on its reduction with PID control”, Proceedings of the 22nd Conference on Process Integration, Modelling and Optimisation for Energy Saving and Pollution Reduction, October 20-23, 2019, Crete, Greece.

(2) Gkionis M., Papadopoulos A.I., Shen W., Seferlis P., “Development of a Nonlinear Model Predictive Controller of Flexible Structure for Greenhouse Gas Emissions Minimisation in Pulp and Paper Wastewater Treatment Processes”, Proceedings of the 24th Conference on Process Integration, Modelling and Optimisation for Energy Saving and Pollution Reduction, 2021.

The work is supported by European Union and Greek national funds through the Bilateral and Multi-lateral Scientific and Technological Cooperation Greece – China (project code: T7DKI-00426).