Field 1:Simulation, control and diagnosis of wastewater treatment process

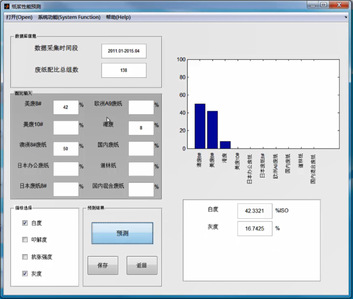

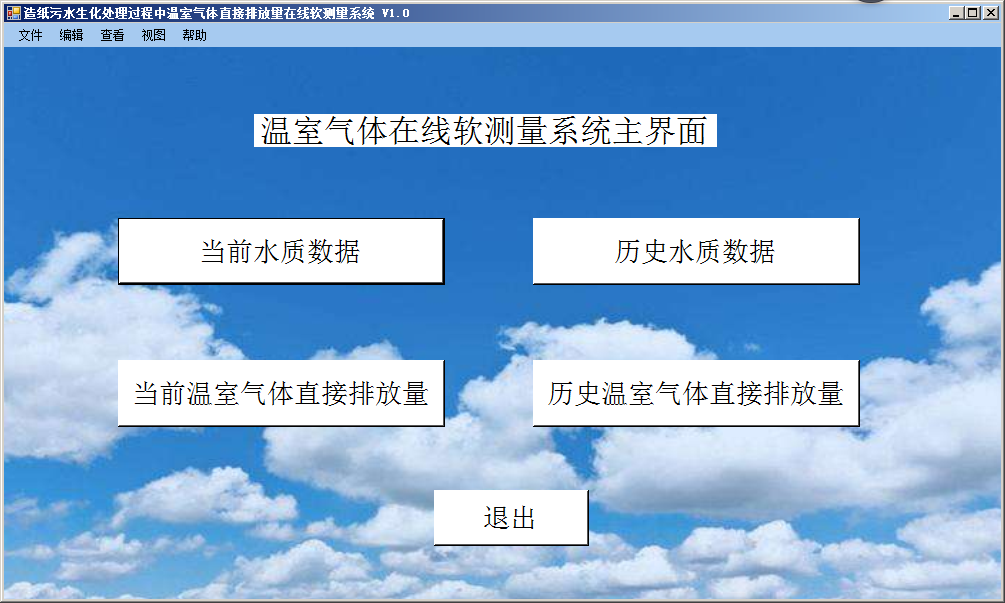

In response to the call of national 'energy conservation and emission reduction', based on ASM1 model, the greenhouse gas emission mechanism model of papermaking wastewater treatment process was established. This model has been verified by the experimental model of greenhouse gas emissions and has certain reliability. The following chart is the main interface of the online soft-sensing system for direct greenhouse gas emissions in papermaking wastewater biochemical treatment process developed by our research group. An energy saving and emission reduction scheme based on intelligent optimal control of dissolved oxygen in papermaking wastewater is proposed by using hierarchical control idea. Compared with open-loop control (aeration rate was 10 h-1), the implementation of optimal control reduced the average aeration rate in the wastewater treatment process by 21 % and the total GHG emissions by 8.55 %.

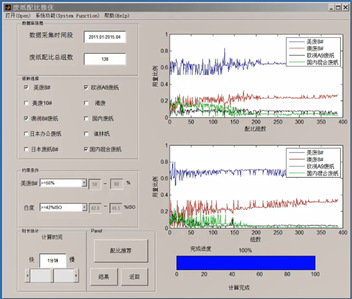

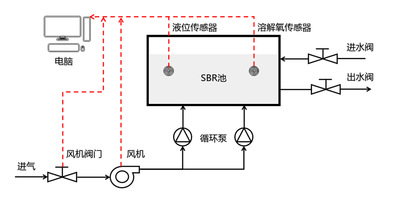

In order to ensure the stable and effective operation of the wastewater treatment process, we have realized the fault diagnosis of papermaking wastewater treatment process based on data and model, and built a fault diagnosis framework integrating fault monitoring, fault location and fault signal reconstruction. The following figure is a simplified diagram of SBR process equipment for papermaking. The process data, such as liquid level, dissolved oxygen concentration and so on, are collected by sensors and input into the fault diagnosis framework to monitor whether the process is in normal state in real time. If there is an anomaly, the alarm is carried out and the fault source is located. At the same time, the fault signal can be reconstructed and restored.

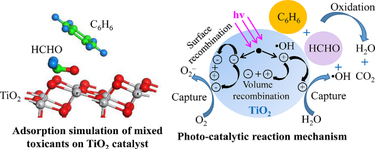

Feild 2: Detection and photocatalytic degradation of industrial waste gas

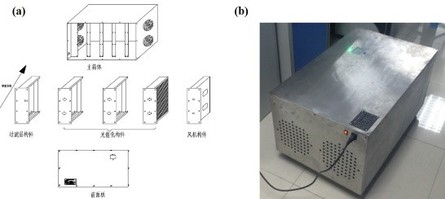

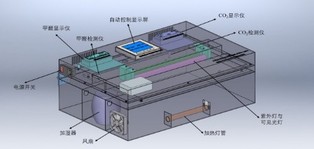

Volatile organic compounds (VOCs) and industrial sewage not only cause lasting damage to the environment but also endanger human health. In view of the lack of understanding of the current situation of ambient air pollution in the paper industry and the weak VOCs control technology, our research group has developed a new type of automatic analyzer with embedded monitoring system, which can detect multi-component gas pollutants in paper mills in real time. Through the systematic analysis of paper environment gases, the chemical characteristics of gaseous pollution sources have been established. From the point of view of molecular microcosm, based on the simulation of energy band structure and gas adsorption behavior of materials by density functional theory (DFT), through the experiment of factors affecting photocatalytic degradation, the photocatalytic degradation mechanism of nano-TiO2 photocatalyst for papermaking polluting gas was studied, and an automatic photocatalytic degradation system for papermaking polluting gas was established. From the point of view of computational fluid dynamics, based on the photocatalytic reaction kinetics of nano-TiO2, the fluid distribution, concentration distribution and radiation field distribution in the photocatalytic reactor were simulated for the design and scale-up study of the photocatalytic reactor. Also, the photocatalytic activity was further improved by means of doping metal elements. Xenon lamp is used as visible light source or UV lamp as ultraviolet light source to realize the photocatalytic degradation of papermaking wastewater and polluting gas.

Feild 3:Synthesis of materials, performance and response mechanism of gas sensors

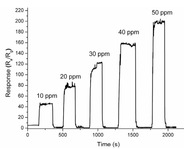

The industrial Revolution of the 1760s brought a huge leap in human productivity and improved human life. But at the same time, due to the rapid development of science and technology, caused severe environmental pollution problems. Air pollution, noise pollution, water pollution and solid waste pollution are listed as one of the four social environmental hazards. Therefore, for the air pollution gas, toxic gas, flammable and explosive gas detection and effective real-time monitoring and early warning has gradually become the focus of the whole community. Gas sensitivity sensors have emerged and become a topic of social science. Nano semiconductor materials have been widely used in the fabrication of gas sensors. Nanomaterials with high crystallinity and strong controllability can be synthesized by anodic oxidation, electrostatic spinning and hydrothermal method. Due to the large number of reaction sites brought by its high specific surface area, the response level is high.

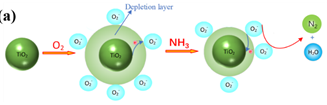

When the material is exposed to air, O in the air adsorbs to the surface of the material. The adsorbed O will acquire electrons from the conduction band to form O ions, forming an electron depletion layer on the surface of the material, making the resistance higher. At the moment of contact with the target gas, O ions adsorbed on the surface will react with the target gas, returning electrons to the conduction band and leaving the surface, reducing the resistance of the material and forming a complete gas-sensitive response.

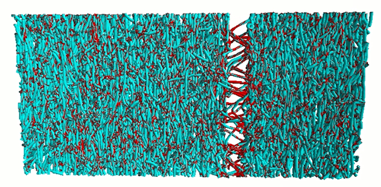

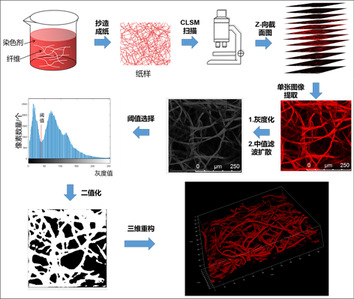

Feild 4:Modeling and Property Prediction of Paper Structure

Computer simulation technology is an effective prediction method for related enterprises and researchers to make various decisions under uncertain conditions based on mathematical model and computer high-speed operation. With the development of computer science and the demand of digital and intelligent development in the field of pulp and papermaking, the computer simulation technology has important research value in the field of paper property prediction. Through the modeling of paper structure and property prediction, the research group hopes to further explore and improve the pulp and papermaking theory, and provide theoretical basis and technical guidance for the research and production of all kinds of new paper. At present, the research contents include: (1) based on the properties of raw materials of papermaking and the product property data, establish a mathematical statistical model to predict the product properties and optimize the ratio of papermaking raw materials, so as to stabilize the product properties and reduce the production cost; (2) based on the mass-spring model, the modeling of papermaking fiber and paper structure is realized, and the mechanical properties of paper are simulated and predicted; (3) based on two-dimensional paper image obtained by CLSM , the paper three-dimensional model is reconstructed, and its porosity and permeability are calculated.