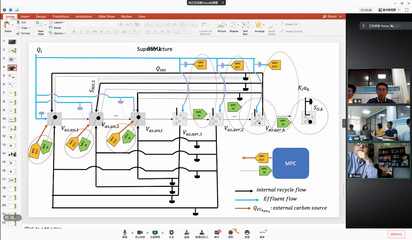

Taking the activated sludge process of papermaking industry wastewater as the research object, combined with the characteristics of large amount of papermaking wastewater and high pollution load, a mathematical model for describing greenhouse gas emission in papermaking wastewater treatment process was established, and the integrated framework of advanced control system, controller’s performance evaluation and sensor’s effectiveness verification is carried out around the goal of greenhouse gas emission reduction. Taking the effluent quality as the constraint condition and the operation cost and greenhouse gas emission as the evaluation index, through multi-objective optimization control, the goal of reducing greenhouse gas emission can be achieved on the premise of meeting the effluent quality and not increasing the operation cost. In view of global climate change, the project will provide theoretical and technical support for realizing greenhouse gas emission reduction in industrial sewage biochemical treatment process from the perspective of automatic control, and put forward the sustainable operation strategy of green paper industry.

Online discussion:

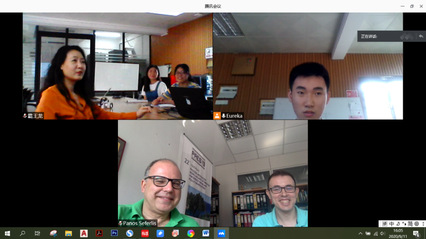

On September 11, 2020, the first remote video conference was held with members of the foreign research team from Aristotle University of Thessaloniki, Greece, aiming at the progress of the phased project.

On March 19, 2021, the second remote video conference was held with members of the foreign research group from Aristotle University of Thessaloniki, Greece, in view of the phased project progress.

On April 13, 2022, the third remote video conference was held with members of the foreign research group from Aristotle University of Thessaloniki, Greece, in view of the progress of the project.

Visiting exchange:

(1) Yin Liu, Guoqiang Niu, Jing Zhou, Wenhao Shen, Jean-Pierre Corriou, and Panagiotis Seferlis. Hybrid intelligent fault diagnosis model based on improved MPCA-V for sensors in a laboratory-scale wastewater treatment process. Industrial & Engineering Chemistry Research, 2022, 61 (50), 18445-18456.

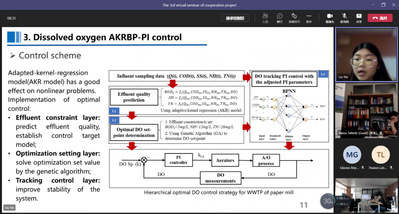

(2) Feini Huang, Wenqing Li, Wenhao Shen*, Panagiotis Seferlis, Yi Man*, Jean-Pierre Corriou. A hierarchical intelligent control strategy for greenhouse gas reduction in wastewater treatment process of paper mill. Journal of Cleaner Production, 2022, Volume 379, Part 2, 134818,.

(3)Zhou, Jing, Feini Huang, Wenhao Shen, Zhang Liu, Jean-Pierre Corriou, and Panagiotis Seferlis. Sub-period division strategies combined with multiway principle component analysis for fault diagnosis on sequence batch reactor of wastewater treatment process in paper mill. Process Safety and Environmental Protection 146 (2021): 9-19.

(4) Marios Gkionis, Athanasios I. Papadopoulos, Wenhao Shen, Panos Seferlis. Development of a nonlinear model predictive controller of flexible structure for greenhouse gas emissions minimisation in pulp and paper wastewater treatment processes,Chemical Engineering Transactions,2021,vol 88.

(5) Feini Huang,Wenhao Shen,Xuewen Zhang,Panagiotis Seferlis. Impacts of dissolved oxygen control on different greenhouse gas emission sources in wastewater treatment process[J]. Journal of Cleaner Production, 2020, 274.

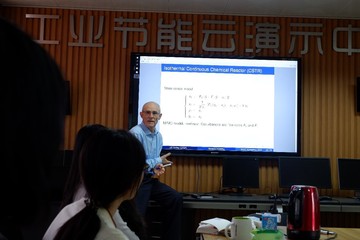

In November 2019, Professor Jean-Pierre CORRIOU from CNRS (Centre national de la recherche scientifique) visited:

Course content: Dynamic modeling, Parameter identification, Control system, Science and technology papesr writing.

Course content:

✓ Physical and mathematical modelling in papermaking science and engineering (I), (II)

✓ Multivariate control of chemical process

✓ Impacts of refining process on the characteristics of pulp and paper

✓ Reducing the energy consumption in the pulp refining process

Course content:

✓ Influence of pulping & papermaking process on the structural and physical properties of papers

✓ How to write and publish high quality papers from the viewpoint of a reviewer?

✓ 3D structures analysis of porous materials

✓ Methods of model validation & Design of validation experiment (Modeling of paper structure)

✓ Common methods for improving the properties of paper sheet (from the technological aspects)

✓ Paper-Based microfluidic technology.

Course content:

✓ Dynamic modeling of chemical process

✓ Complex control system

✓ Multivariate control of chemical process

✓ The identification of chemical process system

✓ Optimal control of chemical process

✓ Application of advanced control algorithm in industry