Platforms and Establishment:

Established in May 2023 under the School of Mechanical and Automotive Engineering, the CAX Industrial Software Research Center is built upon several national and provincial-level laboratories. These include the National and Provincial Joint Engineering Laboratory for Automotive Parts Technology, the National Engineering Research Center for Near-Net-Shape Forming of Metallic Materials, and the Guangdong Provincial Key Laboratory of Precision Manufacturing Technology and Equipment.

Research Objectives:

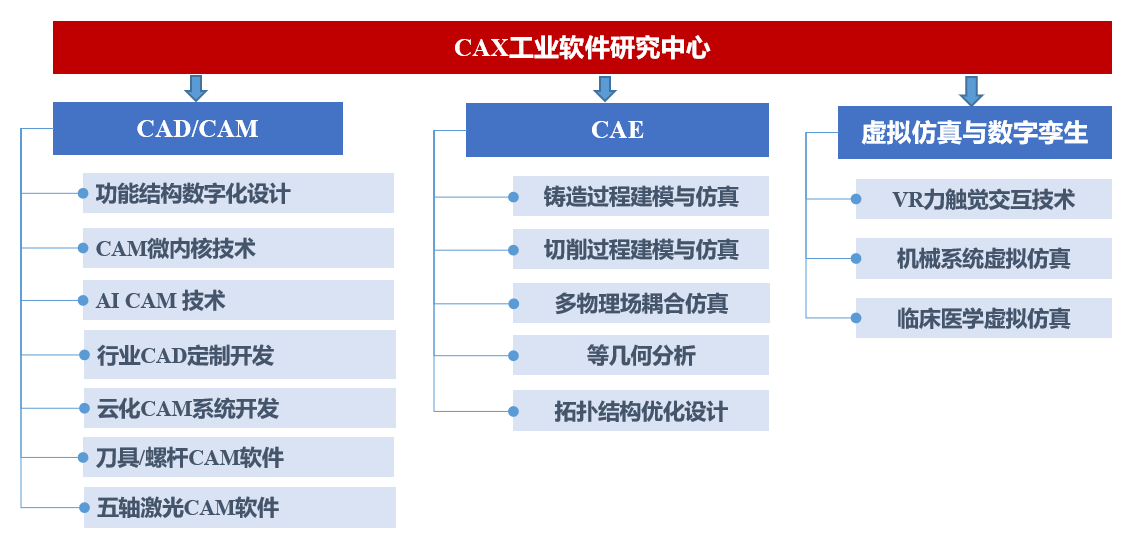

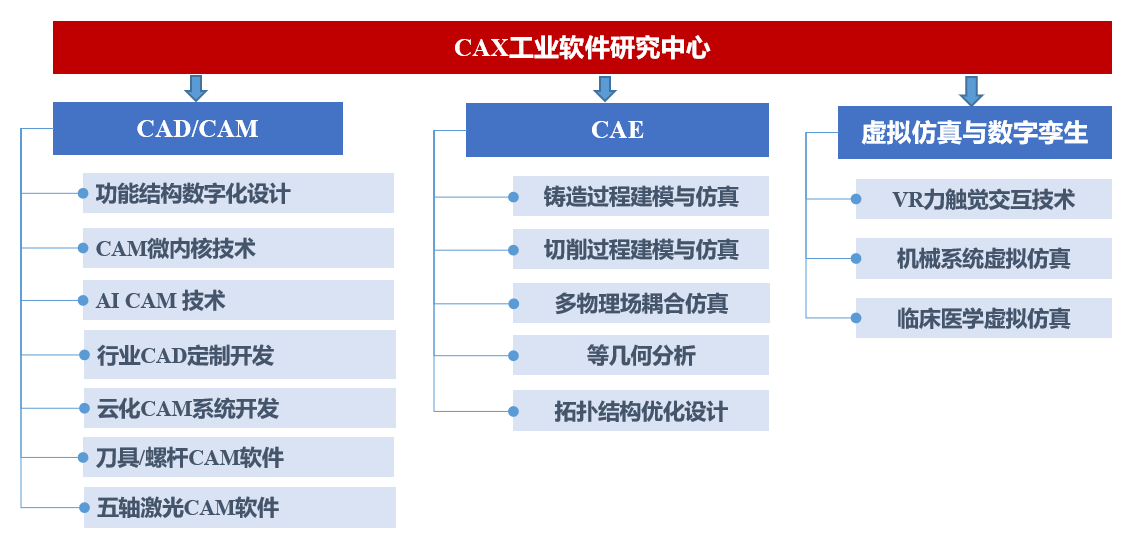

Aligned with the national strategic goals of achieving independence, controllability, and security in core industrial software, and addressing the critical demand for CAX software in regional high-quality manufacturing development, the Center leverages South China University of Technology's comprehensive strengths in engineering disciplines. Through organized, long-term research, we conduct scientific research and tackle key challenges in CAD/CAM, CAE, virtual simulation, and digital twin technologies. We aim to make breakthroughs in core technologies such as CAM kernel development, intelligent CAD assembly techniques, and force-feedback interaction technologies and equipment. The Center seeks to integrate with China's core industrial software R&D ecosystem, contribute to the application landscape, and actively promote high-quality development in both national and local manufacturing sectors.

Team, Foundation, and Achievements:

The Center is directed by Professor Wang Qinghui and comprises 12 full-time researchers, including 8 professors, 2 associate professors, and 2 lecturers, supported by over 150 postdoctoral fellows, doctoral, and master's students. Regarding CAM key technologies, the Center has developed a self-contained CAM micro-kernel with its own compact geometric kernel. This kernel supports 2-to-5-axis CNC toolpath planning, machining interference checking, and machining simulation. All code is independently developed and controllable. It has been successfully applied in various specialized CNC systems, 5-axis laser processing machines, robotic intelligent manufacturing systems, and cloud manufacturing platforms for non-standard parts. Furthermore, the Center has developed a six-degree-of-freedom force-feedback haptic interaction system, which has reached commercial release. Its key technical specifications rival those of internationally renowned brands, and it has been deployed in application demonstrations for robot teleoperation and VR virtual simulation training.

Primary Research Directions:

The Center focuses on CAD/CAM, CAE technologies, and virtual simulation & digital twin technologies. The main research areas include:

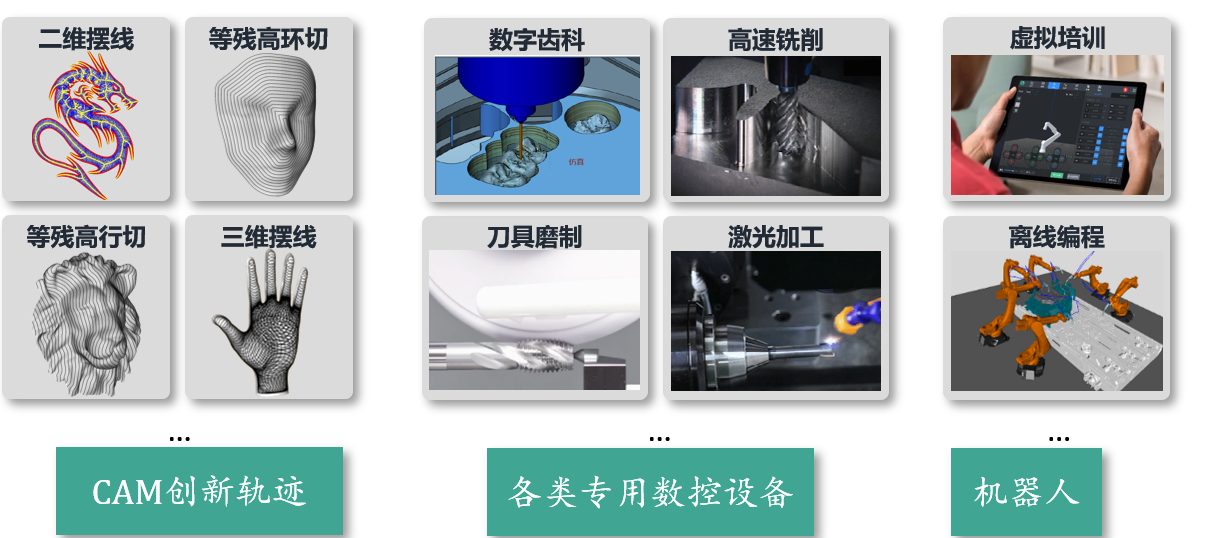

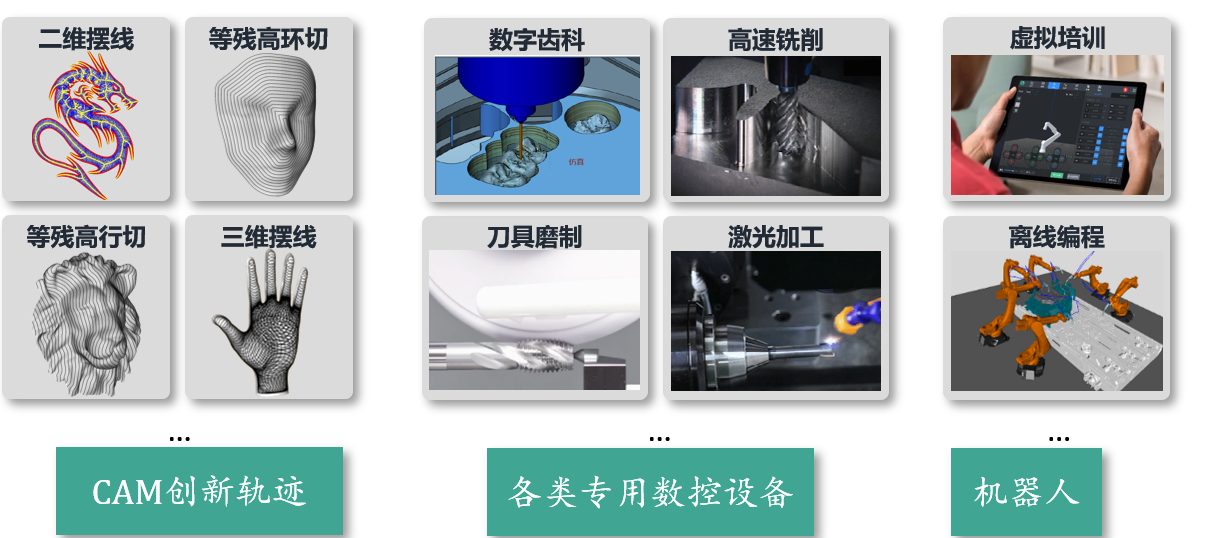

1.CAM Kernel Development

This direction addresses the manufacturing industry's need for independent and controllable CAM kernel technology. It involves the development and continuous iterative optimization of a CAM kernel system, encompassing 2-5 axis toolpath planning, machining interference checking, and machining simulation. The system provides architectural and core module support for toolpath planning and simulation in various CNC equipment. It has already found significant application in multiple specialized CNC systems, 5-axis laser processing machines, robotic manufacturing systems, and non-standard part cloud manufacturing systems in China.

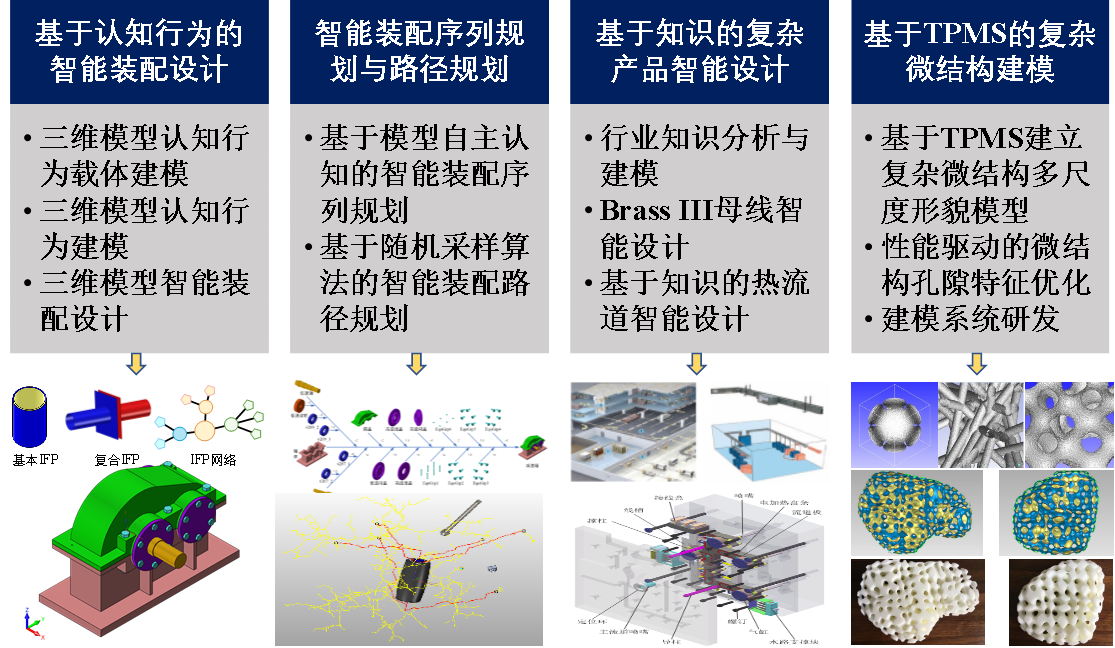

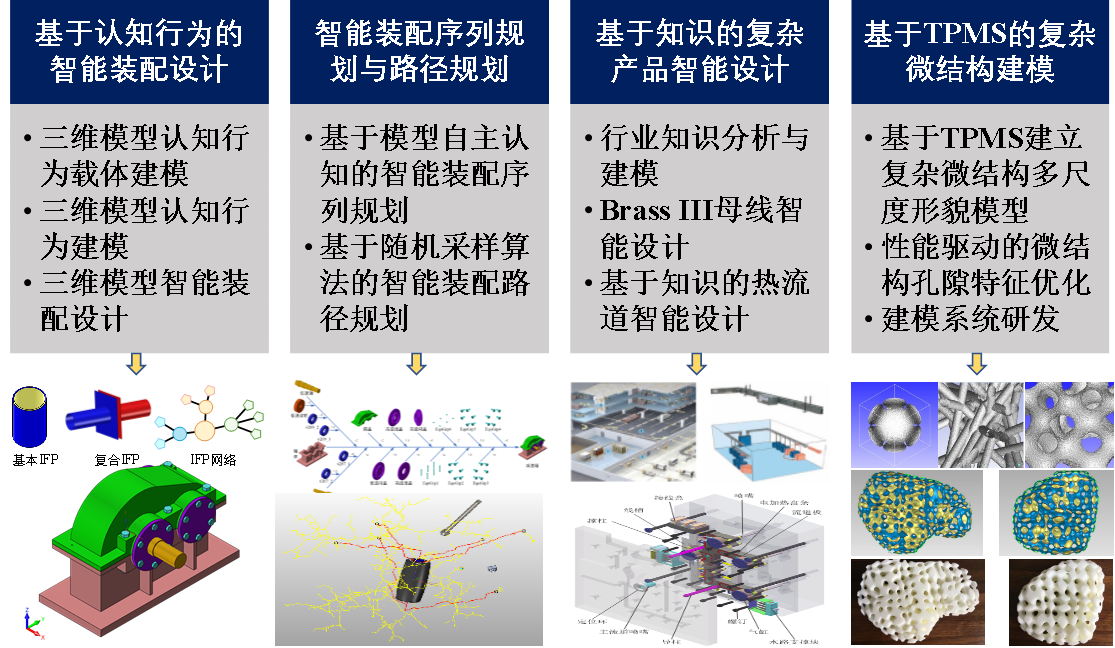

2.Intelligent CAD Development

This research area primarily includes digital assembly technology, intelligent CAD design, and CAD modeling techniques for complex microstructures.

3.CAE Simulation and Optimization

This direction encompasses isogeometric analysis and structural topology optimization, multi-physics modeling and simulation of casting processes, lightweight design and multi-physics coupling simulation of functional structures, and simulation of material deformation, stress, and strain states.

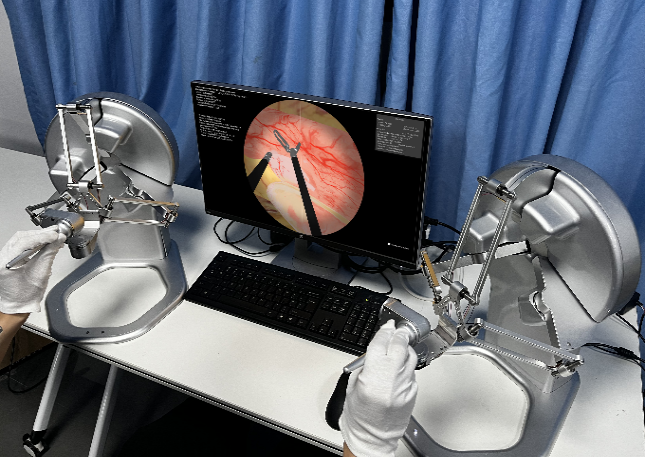

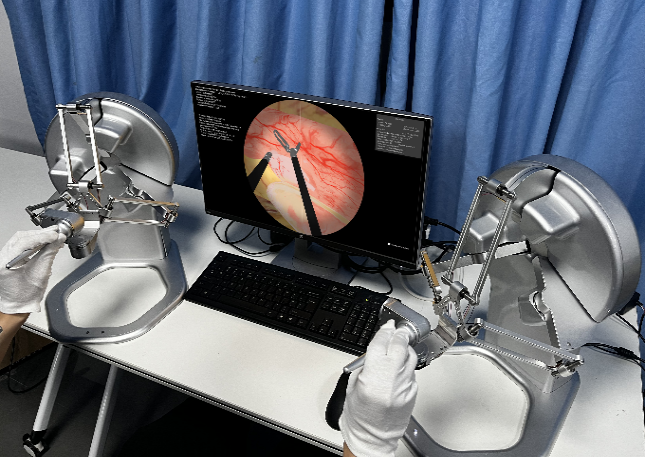

4.Haptic Interaction Systems and Equipment

Responding to the demand for six-degree-of-freedom haptic interaction systems in robot teleoperation and VR virtual simulation, this line of research investigates cutting-edge key technologies and design methodologies for force-haptic integrated VR interaction devices. It has achieved breakthroughs in key technological objectives for series-produced 6-DOF force feedback end-effector devices, including lightweight hybrid-structure integration, rapid and precise positioning, and dynamic gravity compensation, resulting in a systematic intellectual property portfolio. To date, the Center has successfully developed proprietary series and parallel 6-DOF force feedback devices, completed commercial model development, and achieved demonstrative applications in key teaching, research, and industrial units for robot teleoperation, novel medical devices, clinical medical skill training, and equipment maintenance operation simulation training.

Contact: Wang Qinghui,Email:wqh@scut.edu.cn