Supported Platforms

The Research Center of Intelligent Polymer Manufacturing (RCIPM) is established in May 2023 under the School of Mechanical and Automotive Engineering, which is supported by several national and provincial-level laboratories, including: National Engineering Research Center of Novel Equipment for Polymer Processing, National Engineering Laboratory of Plastic Modification and Processing, the Key Laboratory of Polymer Processing Engineering of the Ministry of Education, Guangdong Provincial Key Laboratory of Technique and Equipment for Macromolecular Advanced Manufacturing, and Guangdong Provincial Collaborative Innovation Center for High-End Manufacturing Equipment.

Research Center Development Goals

The goal of RCIPM is to establish an internationally advanced research platform in polymer intelligent manufacturing, break through key technological bottlenecks in the high-efficiency molding and intelligent manufacturing of polymer materials, and form a multidisciplinary research team integrating computer science, big data, artificial intelligence, advanced manufacturing, and other fields. The center aims to drive innovation across the entire process of polymer products—from design and optimization to high-precision manufacturing—and is committed to achieving high-performance, high-quality, and high-value-added intelligent manufacturing. It will actively promote original innovation and the translation of achievements in polymer material intelligent manufacturing technology. Oriented toward major national and regional needs, the center will lead the development of polymer intelligent manufacturing technology, provide technical support for high-end equipment, national defense, and the new materials industry, and contribute to the sustainable development and high-quality growth of the national and regional economy.

Research Center Team, Existing Foundation, and Research Achievements

The director of RCIPM is Professor Gang Jin. The center has a permanent staff of 20 members, including 12 professors and 8 associate professors. Among them are one academician of the Chinese Academy of Engineering, one expert receiving special government allowance from the State Council, one young Changjiang scholar, one leading scientific and technological innovation talent under the Guangdong Special Support Program, one recipient of the Guangdong Outstanding Youth Science Fund, and one outstanding young top-notch talent in scientific and technological innovation under the Guangdong Special Support Program.

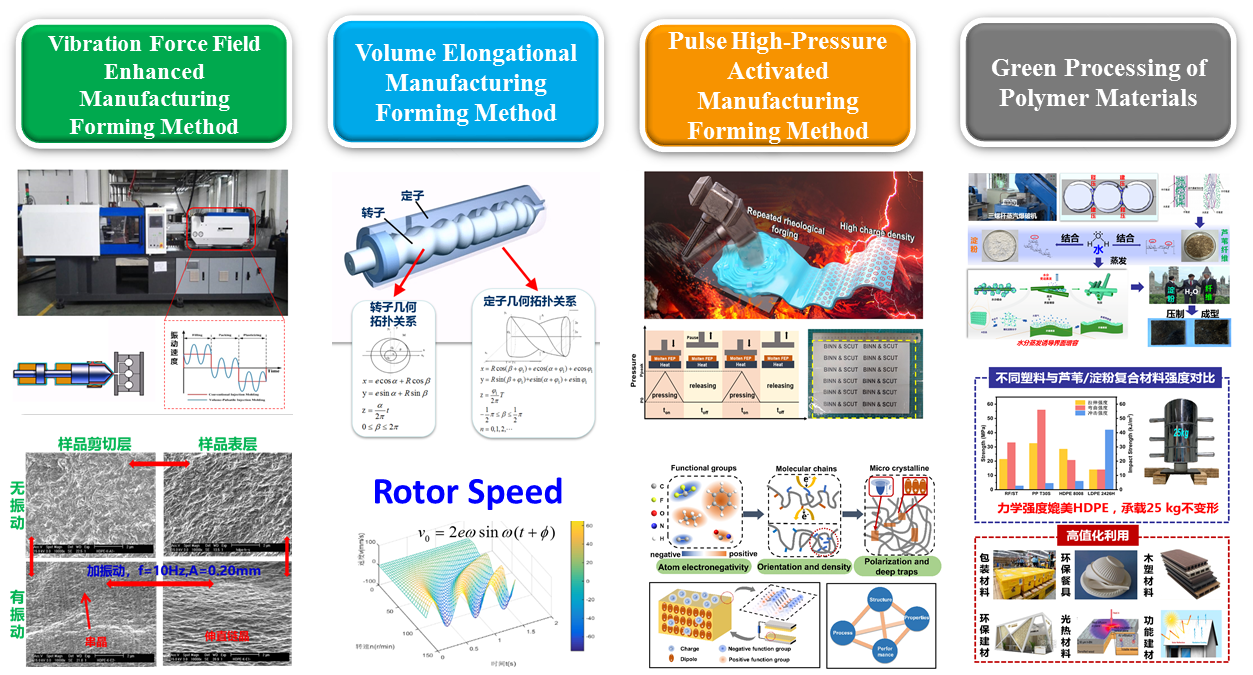

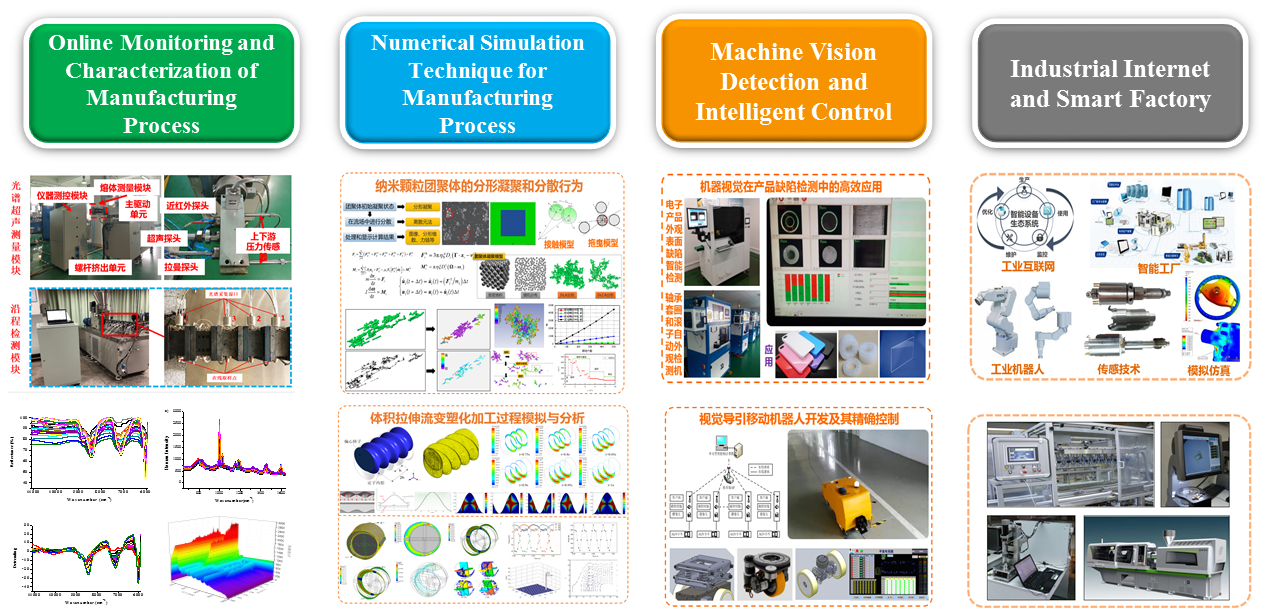

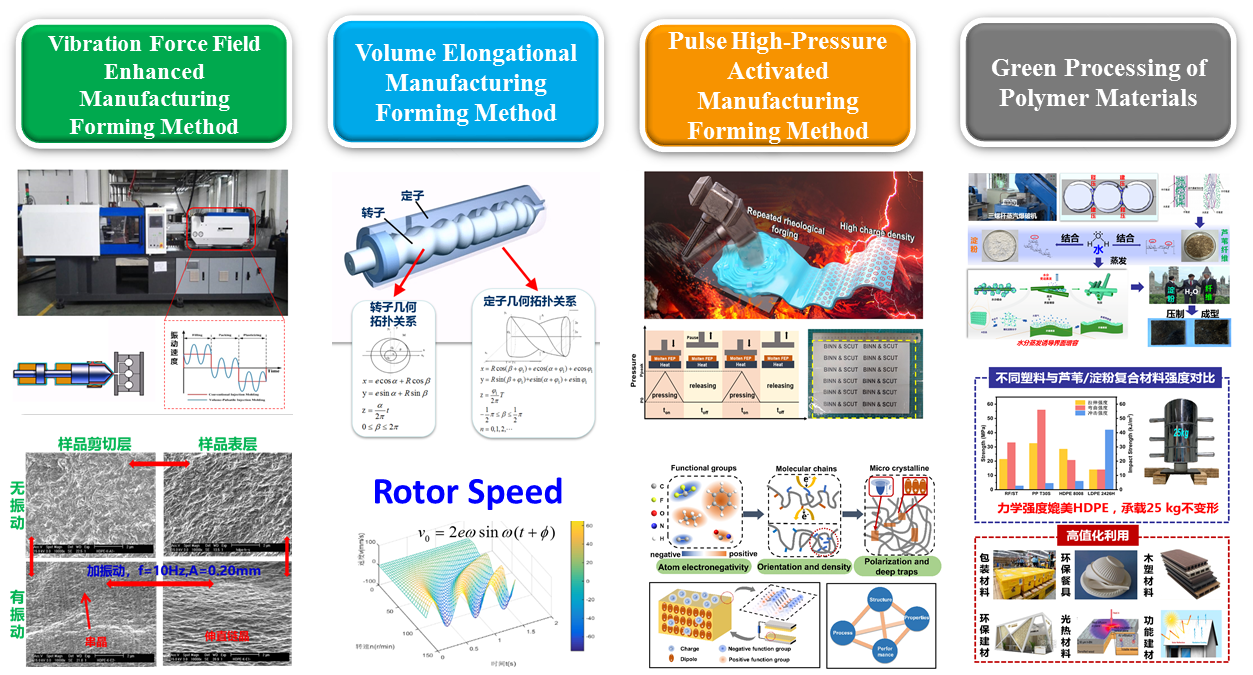

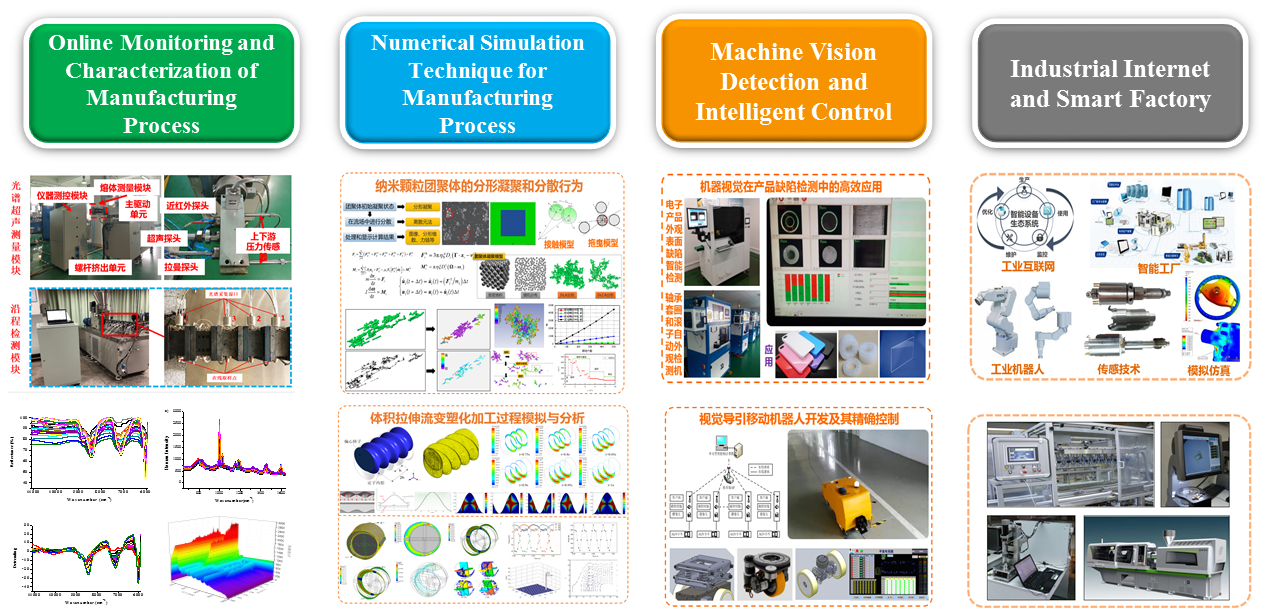

In the field of green processing of polymer materials, the center has proposed a series of original methods, including the Vibration Force Field Enhanced Manufacturing Forming Method, the Volume Elongational Manufacturing Forming Method, and the Pulse High-Pressure Activated Manufacturing Forming Method, thereby breaking away from the century-old development paradigm of polymer processing technology symbolized by the screw. Regarding the intelligent manufacturing of polymer products, the center has made breakthroughs in a range of key technologies, such as online measurement and simulation of the polymer product manufacturing process, big data-driven self-optimization of product form/performance and health self-diagnosis, and machine vision-based online inspection with AI recognition of hidden defects. These advances have laid the foundation for the unmanned, high-quality production of polymer products.

In recent years, the center has undertaken over ten major national-level projects, including those under the National Key R&D Program, the National Major Scientific Instrument Development Project, and key projects of the National Natural Science Foundation of China. Related achievements have earned numerous awards, including two National Technology Invention Second Prizes, one National Science and Technology Progress Second Prize, one China Invention Gold Award, two China Excellent Patent Awards, and eight provincial/ministerial-level first prizes for science and technology. The center's researchers have published more than 1,000 papers indexed in the three major citation databases (SCI, EI, ISTP) and have been granted over 500 patents of various types.

Main Research Directions of the Research Center

RCIPM is dedicated to addressing the critical needs for polymer material products and their processing technologies in key national sectors, including high-end equipment, new materials, new energy, aerospace, transportation and logistics, electronic information, national defense and military industry, and biomedical fields. The center focuses on the following three research areas for fundamental research, technological development, and promotion.

Research Direction 1: New Principles, Methods, and Equipment for Polymer Processing and Forming

This direction focuses on research related to the application and development of stretch-flow rheology plasticizing transport technology and equipment, innovative processing techniques and equipment for extremely difficult-to-process polymer materials, green and low-carbon processing technologies and equipment, and the application of green processing for polymer materials. Key research areas include short-process high-efficiency manufacturing technology for ultra-high molecular weight polyethylene, advanced manufacturing and recycling of fully recyclable high-strength mulch films, and advanced manufacturing equipment for multifunctional composite films based on low-carbon principles.

Research Direction 2: Polymer Intelligent Manufacturing Methods and Smart Factory Technology

This direction focuses on the application of internet, big data, artificial intelligence, virtual reality, and other advanced technologies in polymer synthesis, processing, and production. Key research areas include online measurement and characterization technologies and systems, numerical simulation techniques for processing, machine vision inspection and intelligent control, smart factory planning and design, as well as digital twins for polymer manufacturing and their core software.

Research Direction 3: Polymer New Product Design, Preparation, and Forming Technology

This direction primarily focuses on integrated function-structure-forming design and optimization technology along with related software, 3D printing technology and equipment for polymers and their composites, micro-manufacturing processes and equipment, as well as the design, manufacturing processes, and equipment development for extremely large-sized products.

Contacts: Yingjun Wang, wangyj84@scut.edu.cn