The Industrial Artificial Intelligence Research Center of the School of Mechanical and Automotive Engineering was established in May 2023. It primarily relies on provincial and ministerial-level laboratories, including the Guangdong Engineering Research Center for Robotics and System Integration, the Guangdong-Hong Kong Joint Innovation Platform for Big Data and Computational Intelligence, the Guangdong Key Laboratory of Computational Intelligence and Cyberspace Information, the Guangdong Key Laboratory of Precision Equipment and Manufacturing Technology, and the SCUT-CIMC Joint Innovation Laboratory.

The research center aims to achieve breakthroughs in key industrial AI technologies such as intelligent sensing, intelligent computing, precision equipment, digital twins, and intelligent operation and maintenance, establishing a technology innovation system centered on industry-academia-research integration. The center carries out industry- academia -research collaboration and the transformation of applied research outcomes, to address the needs of key industries such as automotive and electronics manufacturing, and finally forms a vital source and support platform for independent innovation in industrial technology. Furthermore, the center strives to build a top-tier platform for discipline construction and talent cultivation in the interdisciplinary field of intelligent manufacturing, ultimately as a leading domestic innovation platform for openness and resource sharing.

The Industrial Artificial Intelligence Research Center is led by Professor Weihua Li and comprises 13 members, including 4 professors, 8 associate professors, and 3 postdoctoral researchers. Integrating the disciplines of mechanical engineering as well as computer science and technology, the center leverages interdisciplinary strengths to conduct research focused on key technologies in industrial artificial intelligence.

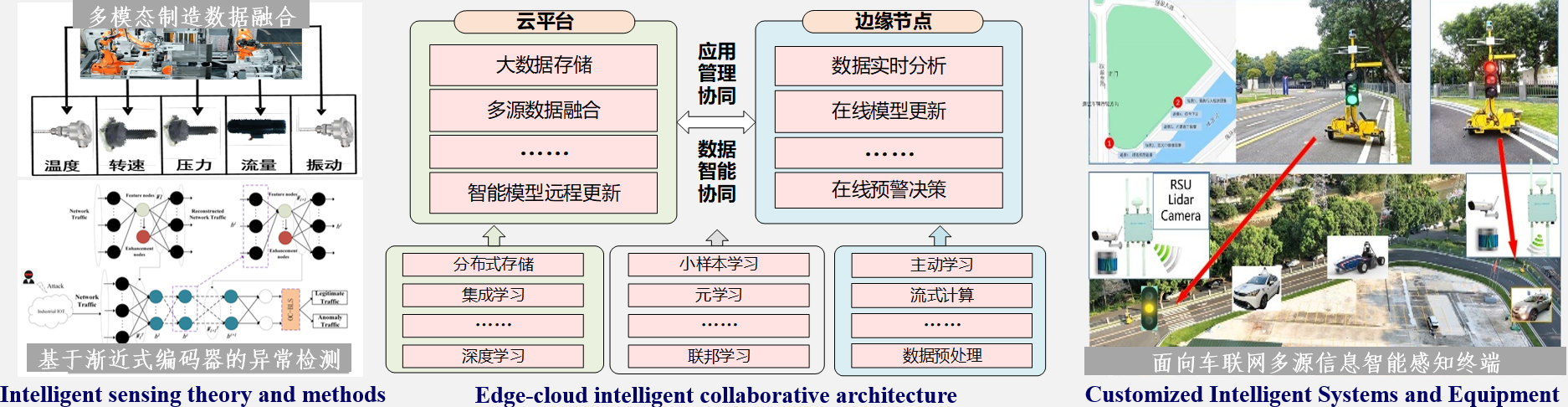

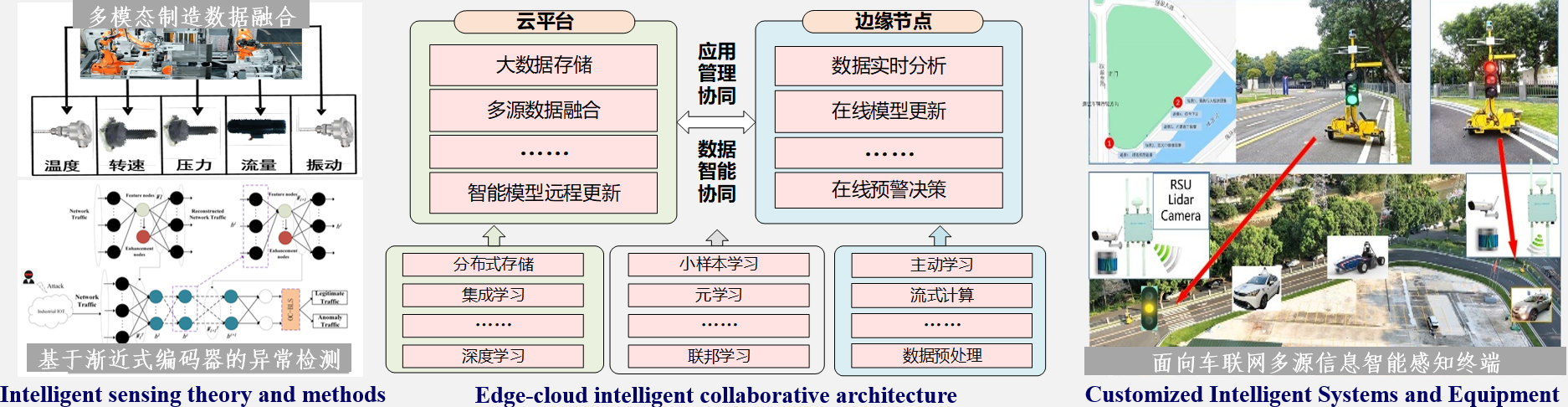

In the field of intelligent sensing systems and equipment, the center has proposed an edge-cloud collaboration and system optimization strategy driven by industrial big data. It has overcome key technical challenges, including the construction of edge-cloud collaborative industrial Internet systems, the embedding and deployment of core industrial intelligence algorithms within edge-cloud architectures, and the optimization of production line operations. The center has established a software platform for the edge-cloud collaborative intelligent processing of industrial process big data, conducting demonstration applications and promotion at several renowned domestic manufacturing enterprises, such as FAW-Volkswagen and Changan Automobile.

In the field of intelligent system operation and maintenance, the center has established theories for intelligent analysis and representation of fault information derived from mechanical vibration monitoring data, as well as interpretable and highly generalizable intelligent transfer diagnosis theories applicable to general scenarios across diverse mechanical equipment domains. The center has also proposed equipment health assessment and remaining useful life prediction methods driven by both knowledge and data, overcoming challenges related to the accuracy and reliability in the dynamically prediction of equipment performance degradation. The core industrial intelligence technologies and software systems developed by the center have provided solid technical support for the intelligent operation and maintenance of high-end manufacturing equipment in both state-owned and private enterprises, generating direct economic benefits exceeding 1.1 billion yuan. To date, the research center has received multiple provincial and ministerial-level science and technology awards. It has undertaken over 100 research projects, including more than 50 national-level projects and over 60 provincial/ministerial-level projects. Additionally, the center has published over 500 high-quality papers (with more than 300 indexed in SCI), and obtained over 100 invention patents and software copyrights.

The research center focuses on technologies such as intelligent perception, digital twins, intelligent operation and maintenance, and intelligent sensing. Its main research directions include:

Research direction 1: intelligent sensing systems and equipment

This research direction primarily focuses on precision equipment, such as industrial robots. By leveraging sensing information acquired from various edge nodes (precision equipment) within the manufacturing system, this direction enables the monitoring of operational status across production stages, the coordination of system resources, and the optimization of production scheduling. Consequently, it aims to establish a comprehensive research system that integrates mechanism modeling design, intelligent sensing control, and software platforms, facilitating the development of customized systems and equipment for specific applications. Key research areas include intelligent sensing theories and methods, edge-cloud intelligent collaborative architecture, and customized intelligent systems and equipment.

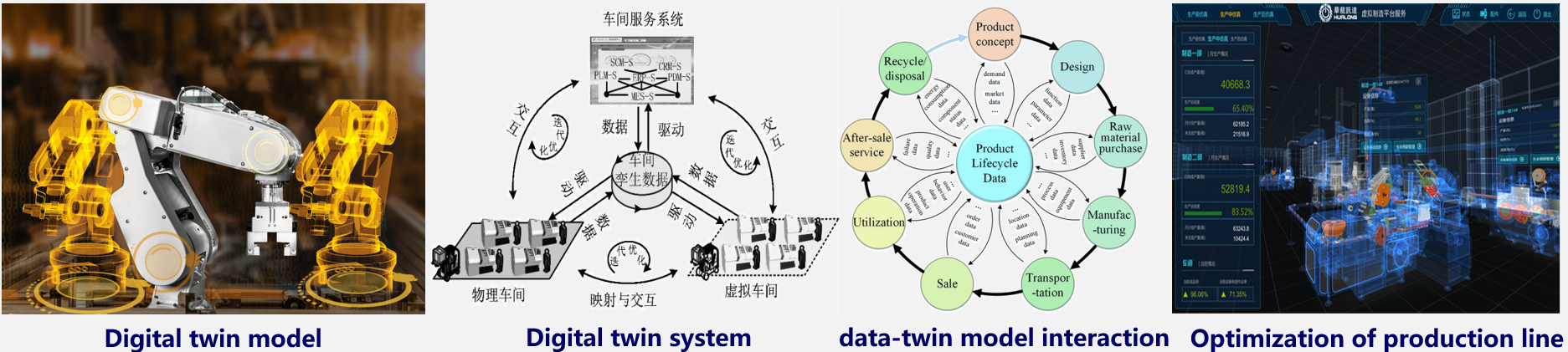

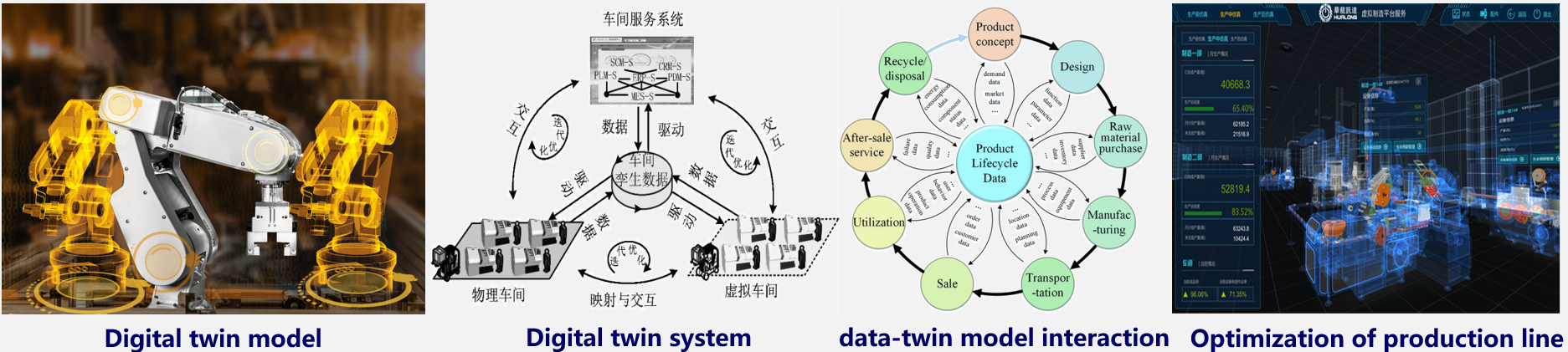

Research direction 2: digital twin intelligent production lines and intelligent workshops

This direction primarily revolves around multi-dimensional integration technologies for the physical, information, and business spaces of intelligent production lines and workshops. By exploring the integration mechanisms and construction methods of multi-disciplinary and cross-domain digital twin models, this direction establishes bi-level iterative intelligent analysis and decision-making algorithm models based on the fusion of models and data. These efforts aim to realize full-process monitoring covering materials, equipment, processes, and products, as well as the dynamic reconfiguration of production lines, thereby facilitating the intelligent transformation of production lines and workshops. Key research areas include the influence mechanisms of digital twin models, software tools for digital twin modeling, and scheduling and decision optimization for discrete manufacturing intelligent workshops.

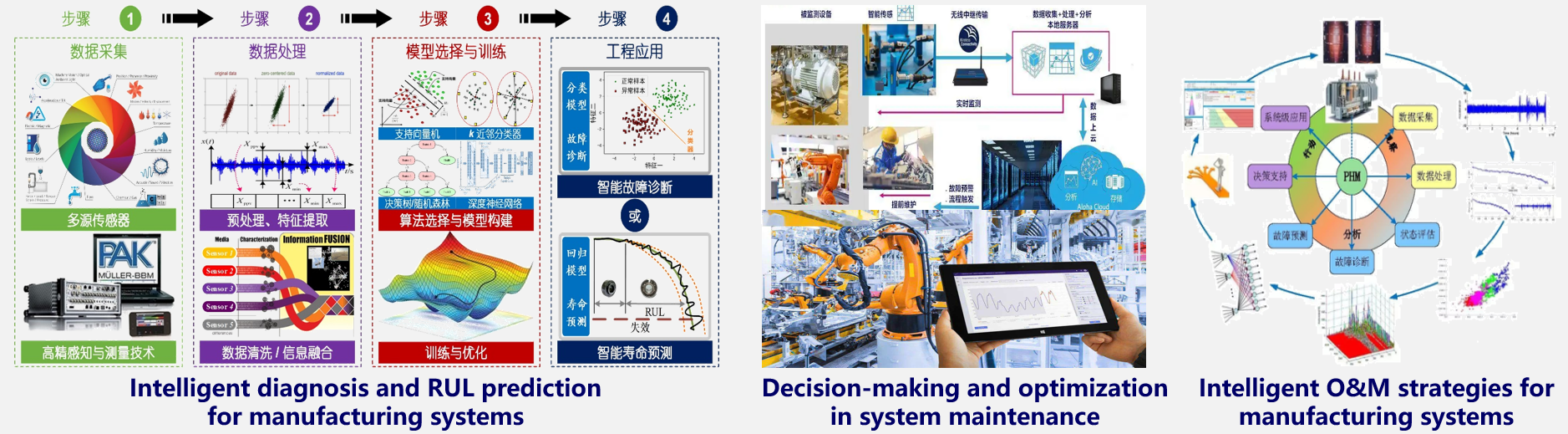

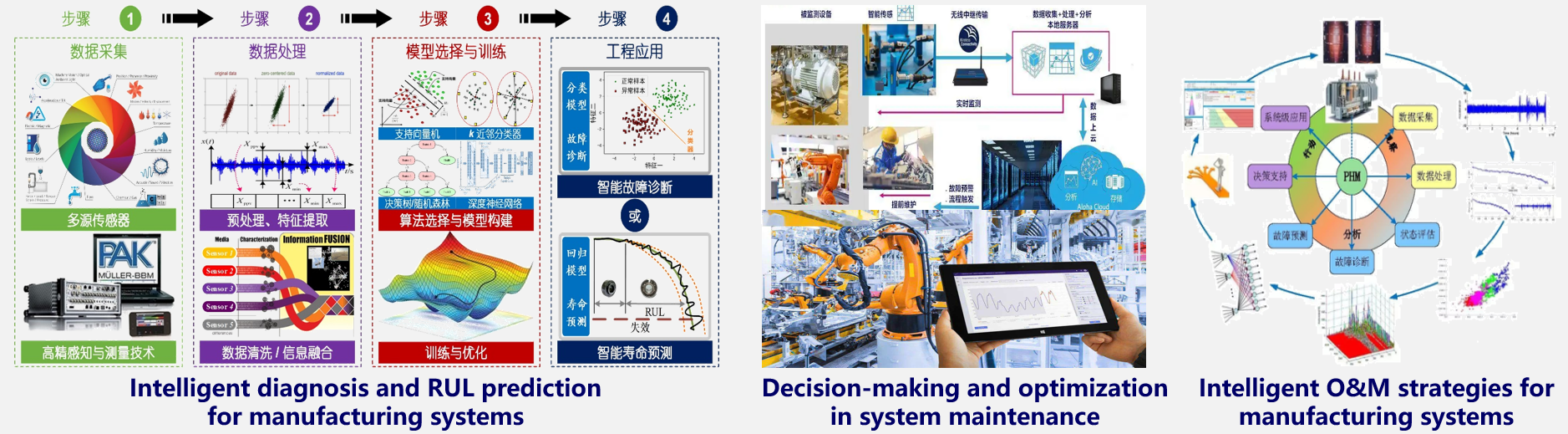

Research direction 3: intelligent operation and maintenance of manufacturing systems

This direction primarily addresses faults and functional failures in manufacturing systems resulting from long-term operation under high intensity, heavy loads, and high utilization rates. This direction establishes intelligent condition monitoring models by achieving breakthroughs in core technologies, such as the mechanisms of service performance degradation, big data-based diagnosis and life prediction, and intelligent decision-making for equipment maintenance. These models facilitate real-time health monitoring of manufacturing systems. Furthermore, by leveraging intelligent decision-making technologies to comprehensively analyze monitoring data, the center aims to formulate maintenance plans that guarantee the safe, reliable, and stable operation of the systems. Key research areas include intelligent equipment fault diagnosis and prognosis, system health status assessment, and intelligent decision-making for operations and maintenance (O&M).

Research direction 4: Intelligent sensing and advanced electronic component inspection

This direction primarily addresses the expanding requirements for sensor modalities, monitoring locations, and data categories driven by the intelligent state perception of equipment and robots. This direction aims to overcome challenges in equipment condition monitoring under extreme service environments, break through bottlenecks in intelligent sensing technology for humanoid robots, and enhance IC defect inspection capabilities in advanced manufacturing processes, forming a new development pattern where manufacturing and inspection mutually reinforce each other. Key research areas include conformal flexible sensors, intelligent skin for humanoid robots, and defect inspection of advanced electronic components.

Contact Persons: Weihua Li whlee@scut.edu.cn

Guolin He hegl@scut.edu.cn