The Precision Equipment and Intelligent Robotics Technology Research Center of the School of Mechanical and Automotive Engineering was established in May 2023, primarily relying on the Guangdong Provincial Key Laboratory of Precision Equipment and Manufacturing Technology.

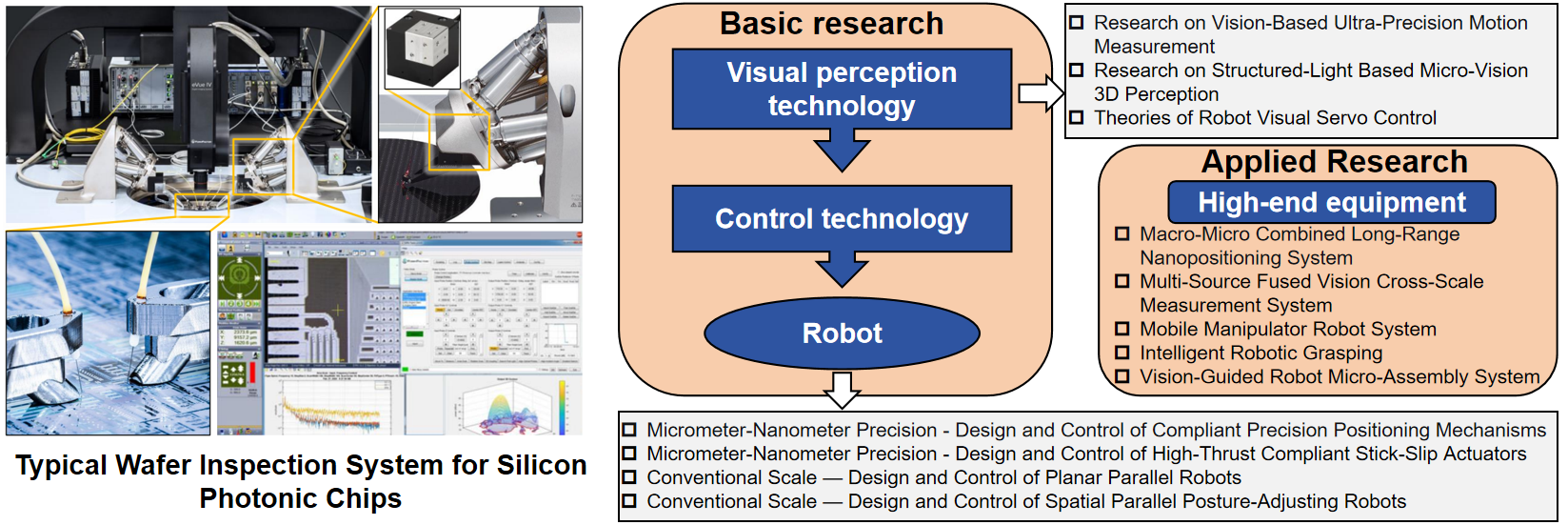

The center is oriented towards international scientific frontiers and major national strategic needs. It is dedicated to research and development of common fundamental theories and core technologies of robotics and intelligent manufacturing equipment. It focuses on key research areas including: mechanism formation principle and design methodology for robots and precision equipment, intelligent visual perception, decision-making, control for robots and precision equipment and system integration and industrial application of high-end intelligent equipment. The center strives to become an innovative service group with strong cultivate capabilities and a hub for the intelligent manufacturing and robotics industry, aiming to lead the development of China's high-end manufacturing equipment and intelligent robotics technology.

The director of the Precision Equipment and Intelligent Robotics Technology Research Center is Professor Xianmin Zhang. The center has a core team of 20 researchers across its various focus areas, including 8 full professors and 5 associate professors. The team includes recipients of prestigious national and provincial talent programs, such as 1 recipient of National Science Fund for Distinguished Young Scholars, 1 recipient of National High-Level Personnel of Special Support Program, 1 recipient of The Science Fund Program for Distinguished Young Scholars (Overseas), and 1 recipient of the Guangdong Provincial Fund for Distinguished Young Scholars, etc.

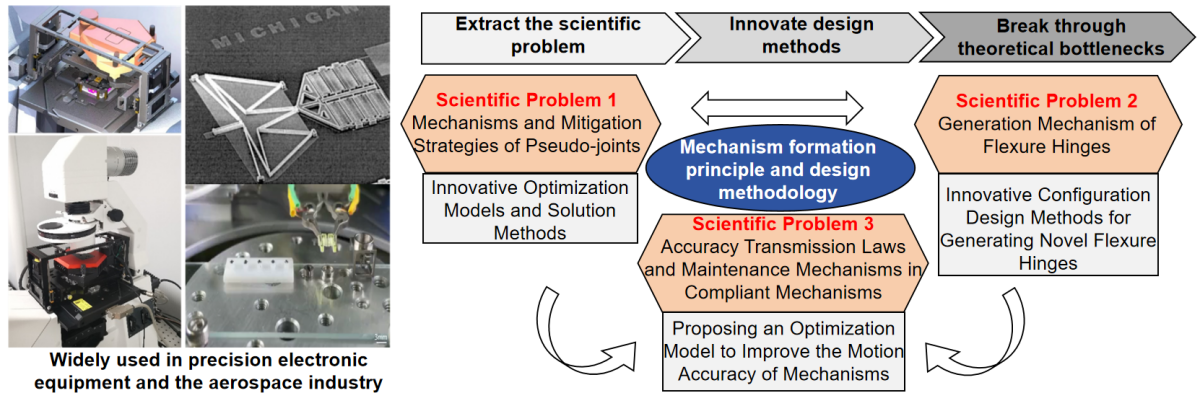

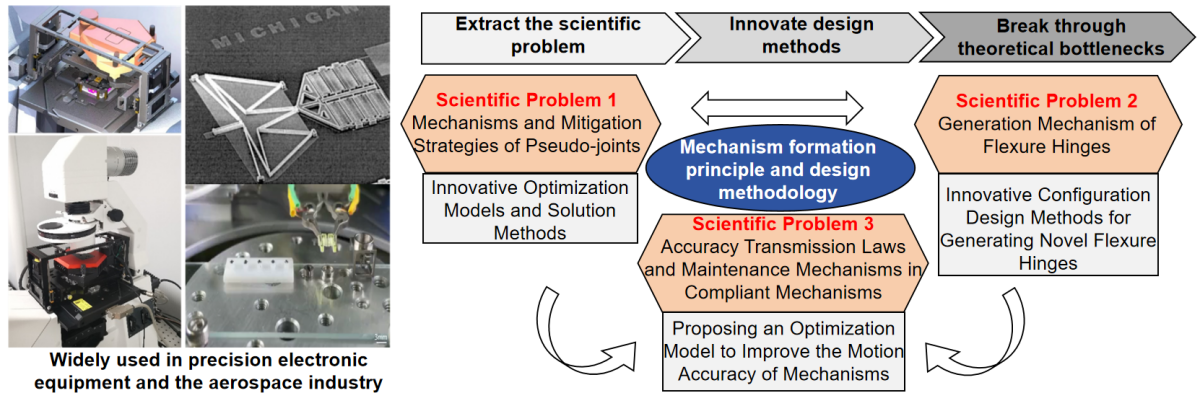

In the area of mechanism formation principle and design methodology for robots and precision equipment, the center has specifically proposed design theories and methods applicable to compliant mechanisms. It has revealed stiffness degradation process in mechanisms during the topology optimization design of compliant mechanisms, solved the pseudo-hinge issue in the topology optimization design of compliant mechanisms, and achieved balanced design of stiffness and compliance of the compliant mechanisms. The center proposed a new collaborative topology optimization design method considering both function and performance for multi-degree-of-freedom parallel compliant mechanisms. It has also introduced a new topology optimization design method for compliant hinges based on the constraint of center of rotation drift, leading to the discovery of a series of novel compliant hinges. Furthermore, the center elucidated the mechanism of input displacement coupling in compliant parallel precision positioning stages, established an input coupling mathematical model, and developed a general multi-objective optimization design method for compliant parallel mechanisms. The research achievements were awarded the First Prize in Natural Sciences of the Higher Education Scientific Research Outstanding Achievement Awards (Science and Technology) by the Ministry of Education.

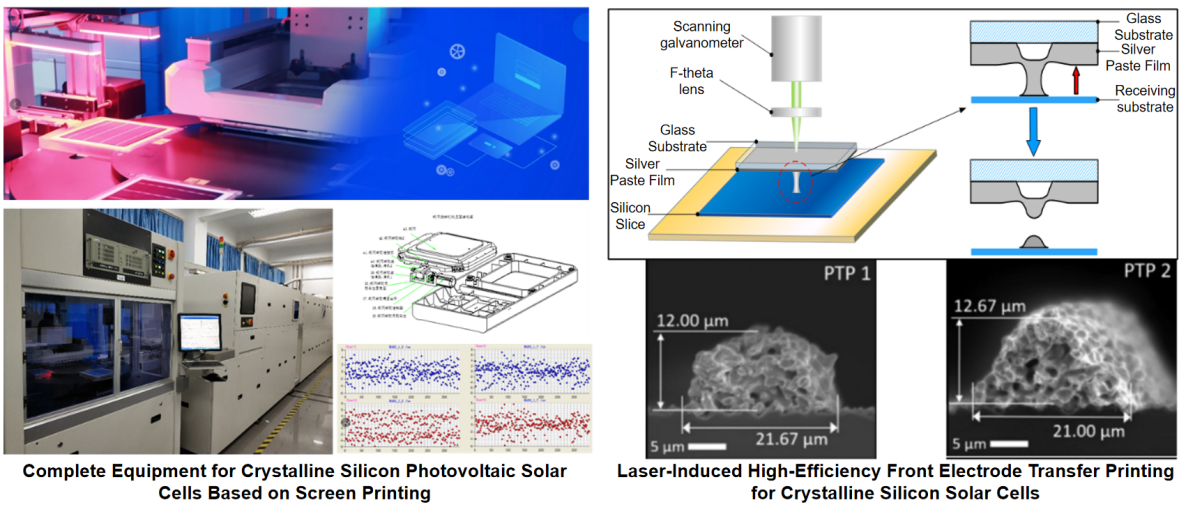

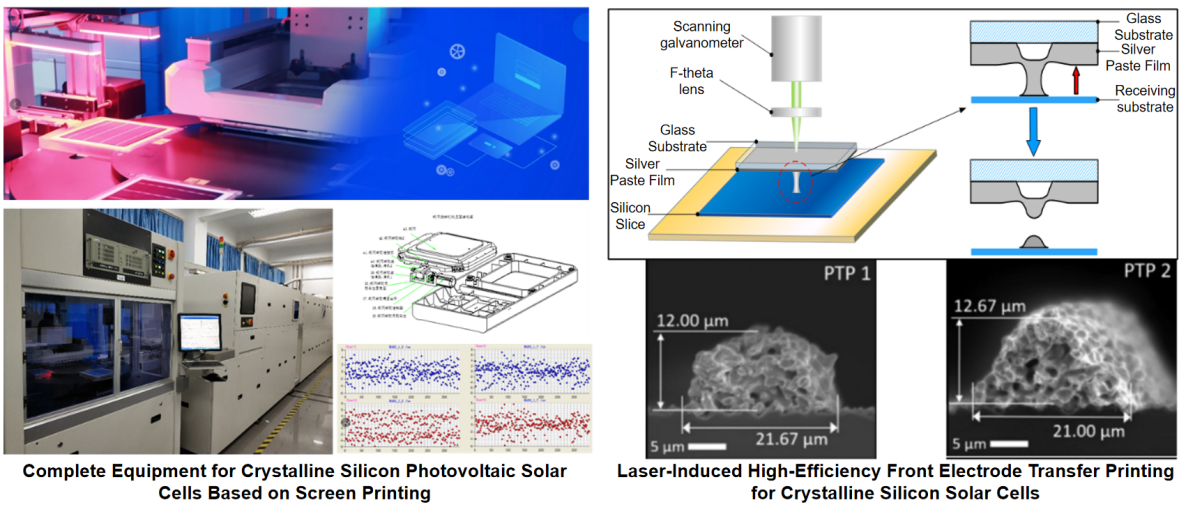

Regarding the system integration and industrial application of high-end intelligent equipment, the center developed key technologies and complete sets of equipment for crystalline silicon solar photovoltaic cells based on screen printing. At the complete system level, it invented key equipment such as crystalline silicon photovoltaic solar cell printers, Drying and Firing System, light-induced degradation test systems, and sorting systems. For common technologies, it invented visual precision positioning systems and calibration methods, achieving fast and precise alignment during the printing process. For key unit technologies, it invented dual-line printing transfer devices, Screen Alignment / Fine-Tuning Mechanism, and a dual-line screen printing and firing process for solar cells. Related achievements were awarded the First Prize of Guangdong Provincial Award for Technological Invention.

The research center focuses on the design and analysis of precision compliant mechanisms, visual intelligent perception and robot control technology, mechanism and robot dynamic analysis and control, and key semiconductor technologies and equipment development. Its main research directions include:

Research Area 1: Mechanism formation principle and design methodology for Robots and Precision Equipment

For high-end equipment whose primary function is realized through mechanical motion, the foremost challenge in original research and development is mechanism design. Research in this direction includes: mechanism formation principle and design methodology for compliant mechanisms; configuration synthesis and optimal design of serial and parallel rigid robot mechanisms; and static/dynamic modeling and analysis of robot mechanisms.

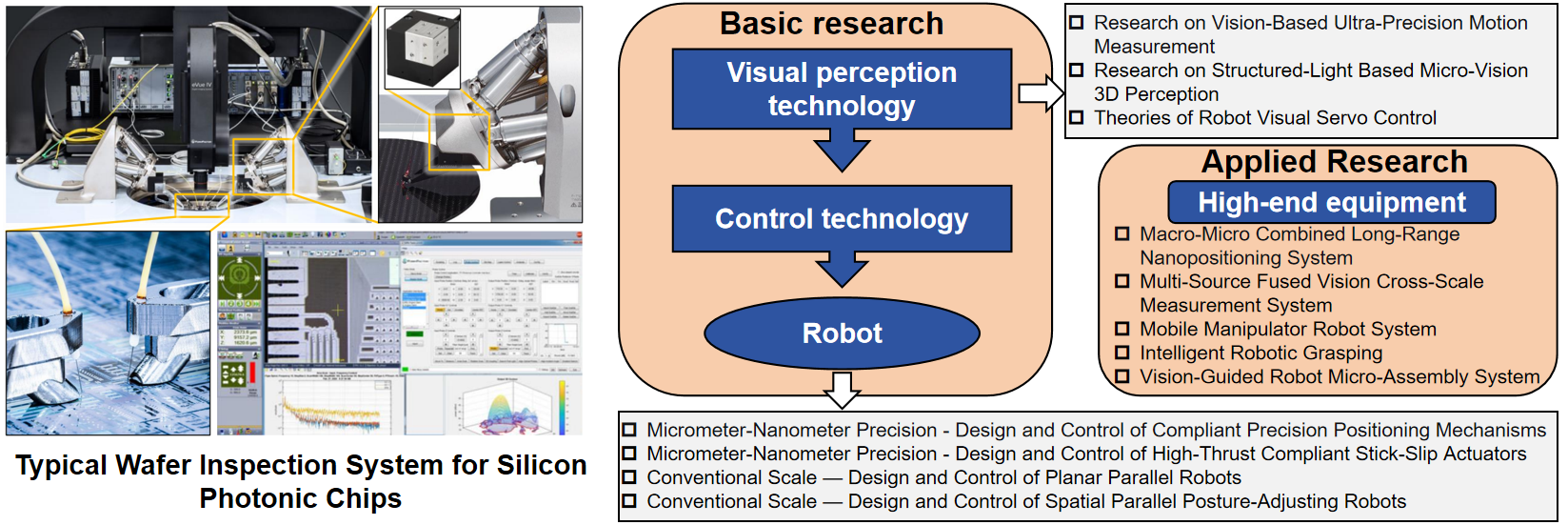

Research Area 2: Intelligent Visual Perception and Decision-Making Control for Robots and Precision Equipment

To enhance the intelligence level of equipment, achieving effective intelligent perception of the working environment and subsequently supporting the control system in making intelligent decisions is a current multi-disciplinary research hotspot. Main research areas include: imaging mechanisms and system design for visual perception systems; ultra-precision target tracking and detection based on 2D image information; scene perception based on point cloud information; vision-guided robot precision control and positioning operations; visual SLAM technology; and robot intelligent control technology based on reinforcement learning.

Research Area 3: System Integration and Industrial Application of High-End Intelligent Equipment

This direction integrates the aforementioned technologies in mechanism design, intelligent perception and decision-making control technologies, conducting research on system integration and application of high-end intelligent equipment in the context of industrial and sector needs. Main research areas include: fundamental research on micro-nano operating systems based on compliant mechanisms and micro-vision; key technologies and systems for adaptive assembly of cross-scale micro-parts; and research and development on key technologies and complete sets of equipment for crystalline silicon solar photovoltaic cell laser printing and semiconductor digital lithography.

Contact Persons: Benling Zhu meblzhu@scut.edu.cn