Energy storage composites

2025-09-29

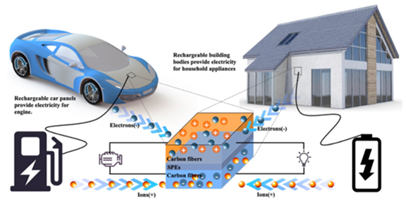

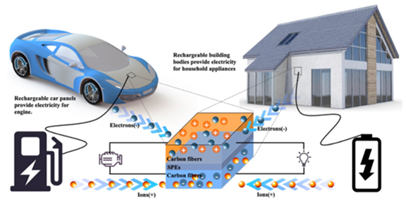

1. Construction of SESDs Based on Fiber Electrodes

Fiber electrodes are utilized to construct quasi-solid-state zinc-based batteries and/or hybrid supercapacitors as energy storage components. Carbon fibers are employed as current collectors, and glass fiber matrices serve as separators. These components are integrated to form devices that operate without flammable organic electrolytes.2. Development of Quasi-Solid-State Electrolytes to Expand Device Voltage Window and Enable Low-Temperature Operation

Deep eutectic solvents are adopted to disrupt the solvation shells of zinc ions and water, thereby forming a water-deficient solvation structure. This approach helps suppress side reactions and dendrite formation at the zinc anode, thus improving the overall electrochemical performance and operational safety of the device.3. Detailed Analysis of Mechanical and Electrochemical Performance

In addition to conducting standard electrochemical and mechanical tests on the prepared electrode materials and devices, an in-situ mechanical-electrochemical testing method developed by our team will be employed. This method allows for the evaluation of the energy storage performance of self-supporting energy storage devices under applied mechanical loads.4. Mechanistic Study of Failure Behavior and Zinc Dendrite Suppression

The interface plays a critical role in the overall performance of the designed supercapacitor energy storage devices (SESDs). Interface failure can be triggered by either mechanical or electrochemical loading. To address this, we will use COMSOL software to simulate the failure behavior between the electrode and electrolyte, and combine the simulation results with experimental data to investigate the underlying failure mechanisms.5. Interface Engineering

Interface engineering strategies—including the design of thin buffer layers, regulation of intercalation hosts, interface pre-treatment, and the use of electrolyte additives—are implemented. These approaches aim to reduce interfacial resistance, stabilize electrode/electrolyte contact, effectively suppress dendrite penetration and hydrogen evolution, and enhance the overall interfacial stability of the battery.6. Electrolyte Engineering

Advanced aqueous electrolyte systems are developed, including functional additives, mixed electrolyte systems, and hydrogel-based formulations. These innovations are designed to broaden the electrochemical stability window, mitigate corrosion reactions, and improve ionic conductivity, thereby enhancing the overall electrochemical performance of the device.7. Solid-State Electrolyte Materials

Exploration of solid-state electrolyte materials—including sulfides, oxides, halides, and polymer-based systems—is conducted. These materials are selected for their high ionic conductivity, wide electrochemical stability range, and excellent thermal stability, providing a robust material foundation for safe and efficient solid-state battery systems.8. Fabrication and Scalability

Innovative, cost-effective, and scalable fabrication processes—such as tape casting, co-sintering, and roll-to-roll processing—are developed. These methods are aimed at advancing commercialization efforts while achieving an optimal balance among safety, performance, and cost.