Traditional polymer-based composites containing nanofillers (in 0D, 1D, and 2D forms) have evolved into a new class of polymer nanocomposites with outstanding mechanical and physical properties. These nanocomposites can be tailored for specific functional applications in industries such as aerospace, automotive, microelectronics, energy, and packaging.

Structural fiber-reinforced composites are widely used in harsh environments such as space exploration, terrestrial transportation, and deep-sea navigation. However, the damage and degradation of their mechanical and physical properties under these extreme conditions have not been fully investigated. These research areas pose significant challenges to the极限 (ultimate) application of fiber-reinforced and hybrid fiber/nanoparticle composite materials.

3. Additive Manufacturing of Advanced Composites

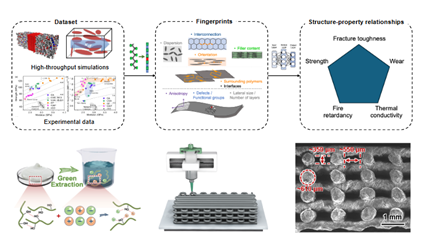

3D additive manufacturing technologies for fiber and nanoparticle-reinforced polymer composites with defined mechanical and functional properties have gained significant attention. In some studies, machine learning and in-situ assisted methods have contributed to improved process design. However, due to unoptimized printing parameters, the resulting products often exhibit defects. Our goal is to simulate the 3D printing process (e.g., FDM) of selected polymer/continuous fiber or polymer/nanoparticle material systems, understand how processing parameters control the quality of the composites, and enhance the final material performance through property-processing relationships.

Polymer nanocomposites are ideal materials for multifunctional applications, but predicting their properties based on composition is challenging due to their complexity. Therefore, a new design paradigm is needed to effectively predict the performance of nanocomposites and establish structure-property relationships to accelerate the design process. This includes leveraging existing datasets, machine learning techniques, and multiscale computational models to study and discover new or improved polymer nanocomposites with specific functional properties (such as fracture toughness, wear rate, thermal conductivity, flame retardancy).

The development of green elastomer material systems—including bio-based rubber compounds and bio-based additives—using renewable biomass resources is an essential pathway to promote the sustainability and greening of China’s rubber materials under the dual-carbon strategy, with profound social impact.

Designing the multi-level network structure of rubber materials—including filler networks, rubber-filler interfacial interactions, and rubber molecular chain crosslinked networks—to suppress microscopic internal friction among various components is key to reducing hysteresis loss in rubber. This is of great significance for energy conservation and achieving high-performance rubber.

Reversible crosslinking offers new opportunities for the recycling of thermoset polymers. However, key challenges in developing practically viable recyclable rubbers include how to easily construct reversible crosslinks in traditional olefinic rubbers, how to balance the trade-off between high-temperature relaxation and low-temperature creep, and how to enable continuous reprocessing of reversibly crosslinked rubbers.

Developing structural-functional integrated elastomeric materials that possess both specific functionalities and flexibility holds significant scientific and practical importance. The main challenge in their design and preparation lies in resolving the conflict between achieving desired functions and maintaining the unique elastomeric properties such as high elasticity, low modulus, and large deformability.