The team of fatigue, damage and fracture mechanics focused on a series of theoretical and experimental research on the durability and safe service of concrete structures in typical sub-tropical service environment. The main research works include: 1) inventing a variety of advanced new building materials to build and strengthen concrete structures; 2) developing the environmental fatigue and fracture theory of advanced materials reinforced concrete structures, and establishing its environmental fatigue/durability evaluation method and technology; 3) Inventing a series of (prestressed) fiber reinforced RC structure technology, and establishing the life extension and durability technology of fiber reinforced/strengthened RC structure under service environment.

2. Multiscale modeling and simulation in mechanics of materials

In Multiscale Research Group, we study on the deformation, damage and fracture of namely brittle materials at different spatial-temporal scales.

The main research works include:

1) Based on local/non-local (continuum-mechanics/peridynamics) coupling models, we simulate the dynamic crack propagation in transparent ceramic;

2)Through a modified model in peridynamics, we investigate the impact-induced failure in mono-/nano- transparent ceramics;

3) By combining molecular dynamics and peridynamics, we aim to establish the link between mechanical strength and nano-/micro-structure in silicon carbide ceramics, as well as the loading conditions;

4) Using quantum mechanical method and molecular dynamic simulations, we explore the plasticity and structural phase transitions in various kinds of crystals at extreme conditions.

3. Dynamic mechanical behaviors of metallic glasses

The dynamic mechanical properties and damage evolution of metallic glasses under impact loading is of great importance and applied value. In this group, Experiments, simulations, together with theoretical analyses are carried out to study the dynamic mechanical behaviors of metallic glasses.

The main research works include:

1) Developing the In-situ measuring and characterization techniques in the experiments;

2) The shear band evolution and failure behavior at different strain rates and loading conditions;

3) The spallation damage evolution behavior under the dynamic impact loading.

4. Mechanical Behavior and Microscopic Deformation Mechanism of High-Entropy Alloys

Multi-principal element alloys (MPEAs) have great potential in the fields of corrosion resistance, fatigue resistance, and high pressure condition. In this group, effects of the Lattice distortion (LD) and chemical short-range order (CSRO) have been proved on defect evolution and deformation mechanism of MPEAs are studied. Decoupled multi-model simulation method and quasi-isentropic loading are used to simulate the tension, creep and impact processes of CoCrNi MEAs. Our works show LD and CSRO can significantly affect the motion of dislocation, the phase transition and the evolution of stacking fault, twins, and void. These results provide reasonable explanations for the characteristic deformation behavior of CoCrNi MEAs.

5. Mechanical behaviors of hydrogels

A hydrogel is a crosslinked hydrophilic polymer network that can absorb and hold a large amount of water. It is considered as a representative of soft matters and demonstrates great potential in biomedical area. We developed a few cutting-edge techniques to evaluate the mechanical behaviors of hydrogel, including a patented method to measure the tensile properties of hydrogel and the largest split Hopkinson pressure bar system heretofore to investigate the impact response of hydrogel in air or in liquid. Based on the experimental findings, microscale and mesoscale models are proposed to elucidate the interaction between the network and water under various strain rates.

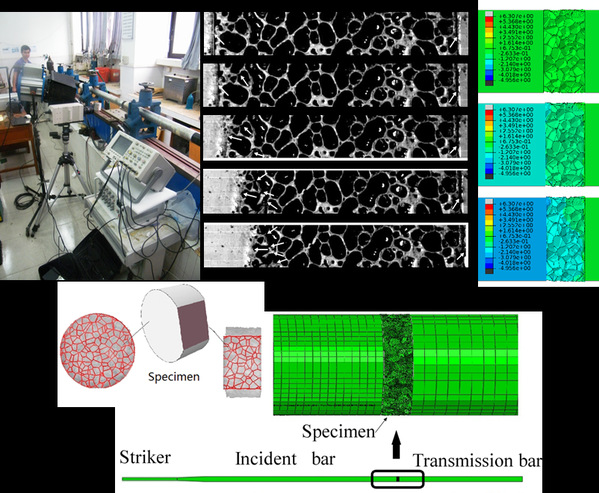

6. Mechanical behaviors of metal foams

Metal foam is a typical cellular material and has found a wide variety of engineering applications due to its attractive properties, such as lightweight, high specific strength, excellent capability for impact energy absorption, and outstanding insulation performance to vibration. The cellular structure endows metallic foams with much more complicated mechanical behaviors compared with bulk materials. Combined real tests and finite element simulation, we constructed the yield and fracture surfaces of Al foam under multi-axial loading conditions and developed impact test methods to eliminate the disturbance of localized deformation.

7. Experiments and modeling works on polymer concrete

Polymer concrete replaces the aggregate or binder in traditional concrete with expanded polymer balls or thermosetting matrices. It is regarded as an excellent engineering material for infrastructures like pavement, drain, arresting system and railway foundation. We produced several types of polymer concrete and studied their mechanical performance under static and impact testing conditions. Based on experimental results, we developed constitutive models for polymer concrete and developed modeling techniques to build high fidelity meso-scale model, which helps the optimization of material design.

8. Multiscale composites

Multiscale composites are also known as multiscale fiber/phase reinforced composites, fiber-reinforced nanocomposites, hybrid/ternary/hierarchical composites. It is a merging of fiber-reinforced composites and nano-technologies. The combination of microscale fibers and nanoscale fillers (nanotubes or nanoparticles) endows multiscale composites superior mechanical performance over traditional composites. Our research focuses on the enhancing effect of nanofillers on the relatively weaker properties of traditional fiber-reinforced composites, such as fiber-matrix bonding and axial compressive strength. We developed a novel fiber bundle composite testing method, which can accurately assess the transverse tensile and interlaminar shear performance of multiscale composites with convenient sample preparation and experimental setup. Based on the experimental data, we developed mesoscale models to bridge the component properties and ultimate strength of multiscale composites.

9. Digital image correlation

Digital image correlation is an optical technique to measure the full-field deformation and motion by matching the image of the object acquired at different moments. It has found many unique applications for deformation measurement at extreme conditions, like soft materials, high temperature, very large and small objects, and underwater. In pursuit of accurate, robust and fast digital image correlation, we developed a path-independent method, which is adaptive to large and complex deformation. Furthermore, we accelerate the method using parallel computing on GPU and keep the highest record of computation speed since 2015, without any compromise of accuracy and resolution. The method has been extended to digital volume correlation, which measures the internal deformation based on 3D volume images.

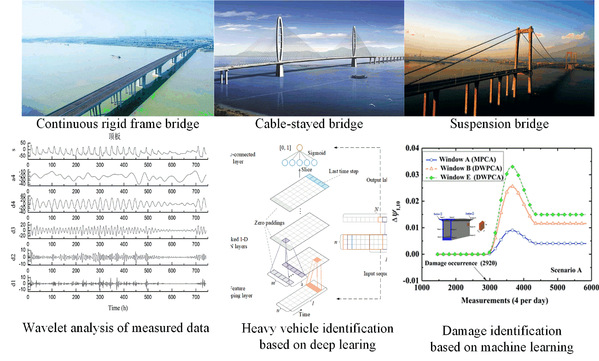

10. Structural health monitoring

Long-term structural health monitoring for bridges and buildings plays an increasingly critical role in our daily life. During the two decades of on-site work, we have established a cloud computing-based health monitoring system to monitor several kinds of long-span bridges, such as continuous rigid frame bridges, cable-stayed bridges, and suspension bridges, and accumulated a large amount of mechanical response data, i.e. displacement, strain, acceleration and cable force, etc. Based on this big data and finite-element simulation, we developed several machine learning-based heavy vehicle detection and damage identification methods to predict the potential danger for bridges under the action of weather, traffic and heavy vehicle accident.

11. Smart wearable structures and systems

Smart wearable structures and systems can wear on the bodies of humans, animals, machines, even buildings, etc. They may be just like a second skin covering the bodies and have the capacity of sensing, actuating, adopting, communicating, seal-healing, self-powering, memorizing, learning, etc. They have many promising applications in healthcare, the internet of things, smart city management, etc. In the last few years, we developed a series of smart wearable structures and systems, such as multi-stimulus-response fabric-based actuators utilized for soft robotic, human-machine interactive and wearable applications, soft pressure sensing units with high sensitivity to pressure, flexible strain sensing units with an ability of large deformation, and wearable energy harvesters based on human motion. Moreover, comprehensive and smart wearable systems also have been developed for enhancing the quality of human life, such as an intelligent system developed to enhance the mobility of people with Parkinson’s disease.