All-acrylic superelastomers: facile synthesis and exceptional mechanical behavior

Wei Lu![]() a, Andrew Goodwina, Yangyang Wangb, Panchao Yin

a, Andrew Goodwina, Yangyang Wangb, Panchao Yin![]() c, Weiyu Wangb, Jiahua Zhub, Ting Wud, Xinyi Lua, Bin Hu

c, Weiyu Wangb, Jiahua Zhub, Ting Wud, Xinyi Lua, Bin Hu![]() d, Kunlun Hong

d, Kunlun Hong![]() *b, Nam-Goo Kang

*b, Nam-Goo Kang![]() *a and Jimmy Mays*a

*a and Jimmy Mays*a

a Department of Chemistry, University of Tennessee, Knoxville, Tennessee 37996, USA.

b Center for Nanophase Materials Sciences, Oak Ridge National Laboratory, Oak Ridge, Tennessee 37831, USA.

c Chemical and Engineering Materials Division, Oak Ridge National Laboratory, Oak Ridge, Tennessee 37831, USA

d Department of Materials Science and Engineering, University of Tennessee, Knoxville, Tennessee 37996, USA

Polym. Chem. 2018, 9 (2), 160-168

DOI: 10.1039/c7py01518f

Publication Date (Web): October 17, 2017

Copyright © The Royal Society of Chemistry 2018

*E-mail: nkang1@utk.edu; jimmymays@utk.edu; hongkq@ornl.gov

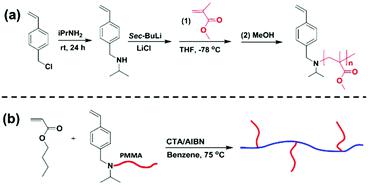

All-acrylic multigraft copolymers, poly(butyl acrylate)-g-poly(methyl methacrylate), synthesized using a facile grafting-through methodology, exhibit elongation at break ( > 1700%) and strain recovery behavior far exceeding those of any commercial acrylic (∼500%) and styrenic (∼1000%) triblock copolymers to date. One-batch anionic polymerization of methyl methacrylate (MMA) using the sec-butyl lithium/N-isopropyl-4-vinylbenzylamine (sec-BuLi/PVBA) initiation system gives PMMA macromonomers with quantitative yield, short reaction time, and using simple synthetic procedures. These new all-acrylic superelastomers and the simple synthetic approach greatly expand the range of potential applications of all-acrylic thermoplastic elastomers (TPEs).