Jointly planned by School of Materials Science and Engineering, South China University of Technology and Guangzhou POI-TECH Intelligent Information Technology Company, seven year-four undergraduates from Materials Innovation Class were offered an off-campus three-week internship chance in POI-TECH Company in Guangzhou Science City.

Founded by research groups led by an academician from SCUT, POI-TECH is committed to using industrial internet and artificial intelligence technologies to improve productivity and reduce costs in traditional process-based manufacturing industry. This practical internship focused on two core contents of “digital transformation of traditional manufacturing industry" and “applications of big data modeling", aiming to enable students to fully understand the intersection and integration of traditional and Internet industry.

Part I: Understanding Digital Transformation

In the first few days of the internship, Bin Yan, Engineer and Head of the Delivery Operations of POI-TECH, explained to the students the application and practice of digital transformation of traditional manufacturing industry, and the difficulties and needs in transformation, such as paper making, cement, glass, ceramic and others. He also talked about the trend of industrial internet, as well as cases of enterprise digital transformation and practice achievements.

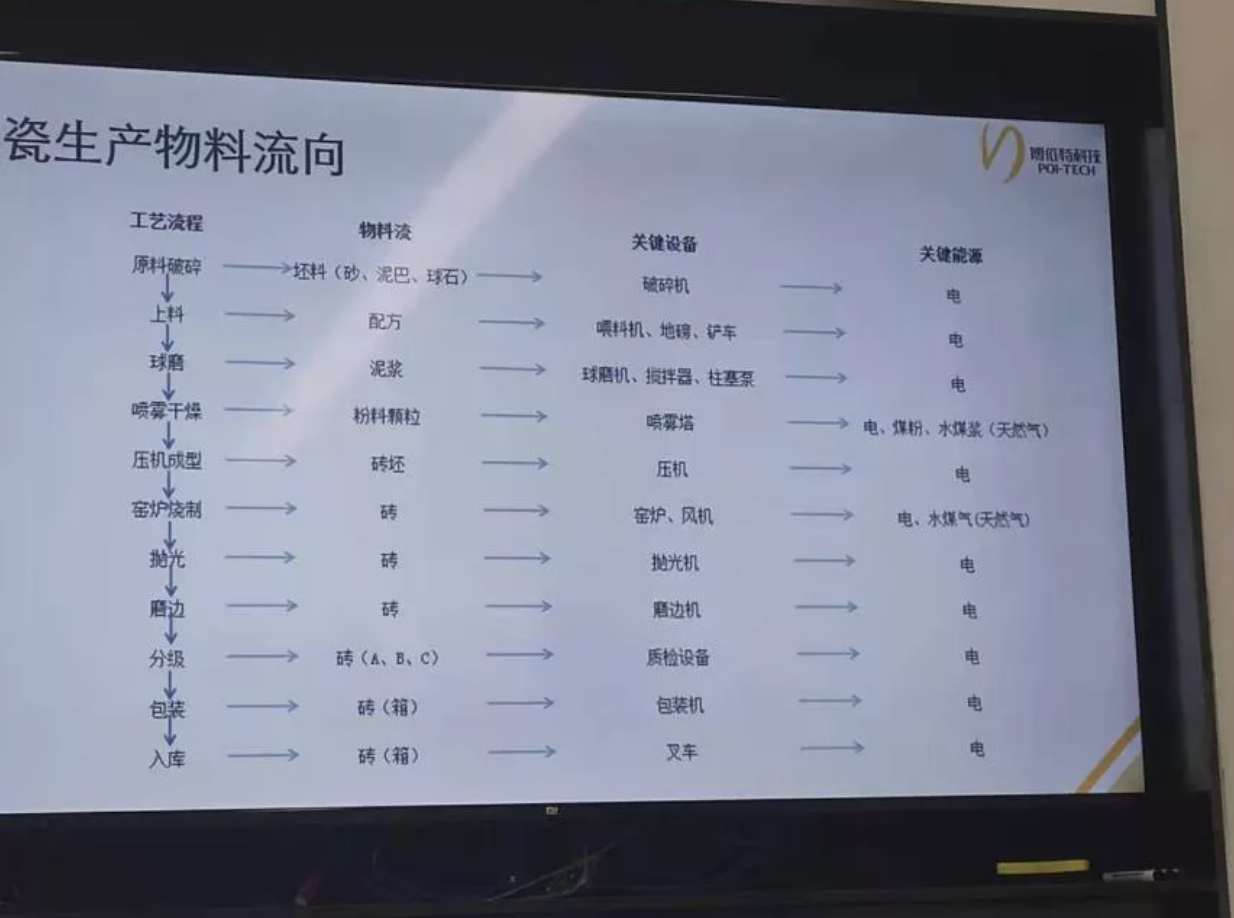

The production process and working procedure of ceramic industry was also introduced, along with the digital production operation platform (POI-Cloud) that is used to increase lean energy efficiency and function value.

Later, students were divided into three groups on cement, glass and ceramic. Each group is designated with the task to collect and report the problems existing in assigned industries. In this process, their understanding of traditional manufacturing and its value of digital upgrading was enhanced.

Part II: Practice of Uploading Data to Cloud

After the introduction on digital transformation, Wenbin Huang, Senior Automation Engineer of Delivery Operations of POI-TECH introduced the basic knowledge of data acquisition to the students, including the data collection service system and the basic flow of data collection. In the hands-on session, students learned how to collect data and upload it to the cloud, and finally displayed it visually in the form of drawing boards.

Part III: Dongpeng Ceramic Factory Tour

In the second week of the internship, students had a tour around the manufacturing factory of Dongpeng in Qingyuan.

During the visit, students not only understood the production process of ceramic enterprises, but also thought about which production line could be optimized to reduce energy consumption. They became familiar with the technological process, material flow, energy flow and key equipment of each process in manufacturing, and had a heated discussion with Bin Yan, Engineer and Head of Delivery Operations of POI-TECH on how to optimize the methods to ensure the correct type and quantity of materials in production.

In the end of the tour, the students were introduced the IT projects of Dongpeng, in which the production data could be directly displayed on the data board for visual processing.

Part IV: Big Date Modeling and Applications

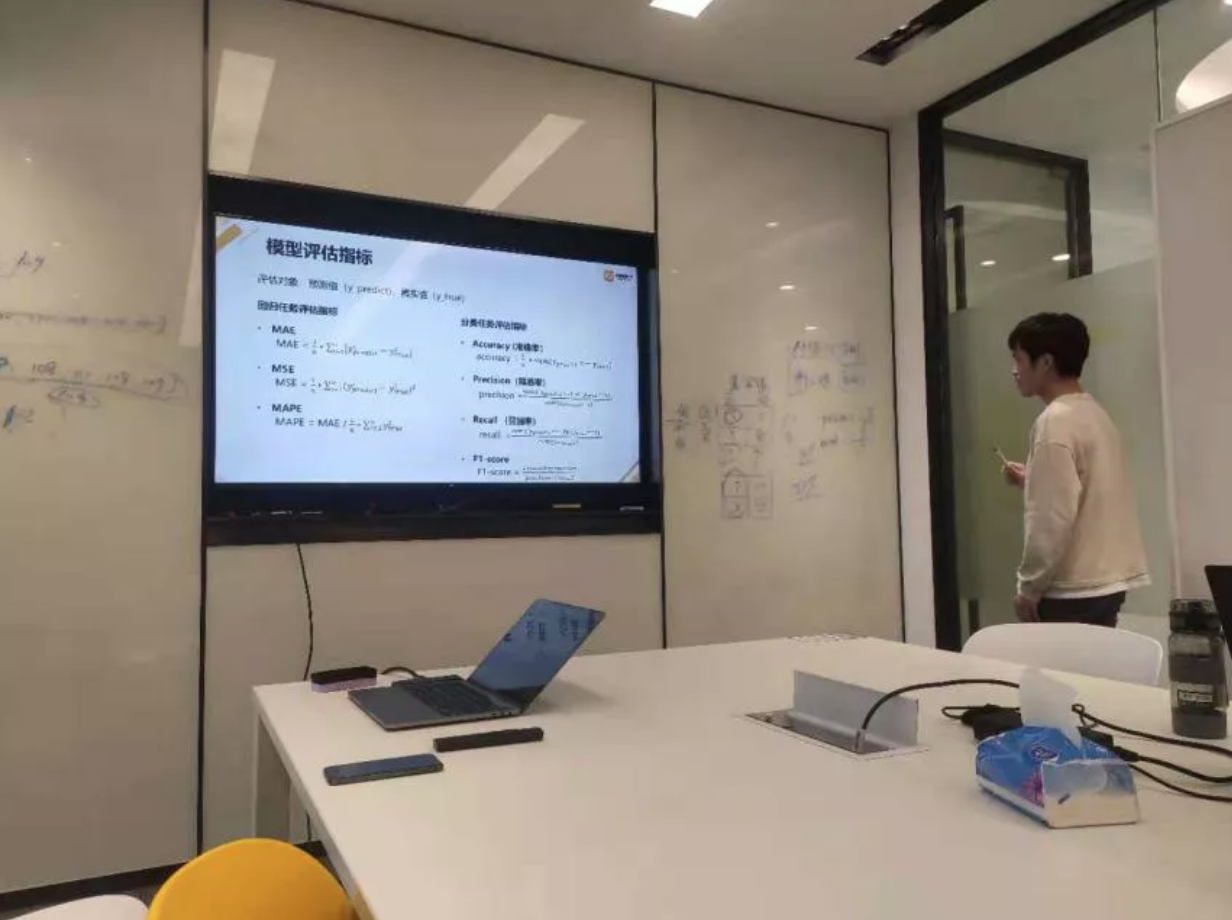

After the tour in Dongpeng, students began to learn common methods and process of data modeling, as well as applications of the best practical models in industry. Tao Huang and Song Hu, AI Algorithm Engineers of POI-TECH introduced python language tools to the students, including big data modeling, common data cleaning methods, basic machine learning algorithms (regression, prediction, classification) and feature screening methods.

Tao Huang and Song Hu also shared several modeling cases of POI-TECH in process industry, demonstrating that the application of big data modeling algorithm can help the process manufacturing industry to achieve cost reduction, efficiency improvement and quality improvement. Students had a deeper understanding of the digital transformation of enterprises and mastered the basic methods of data modeling.

Part V: Group Presentations and Final Defense

On the last day of the internship, each student group gave an oral presentation on the digital transformation of cement, glass and ceramic industry, with information collecting and summary on designated fields of the industry.

The cement group discussed about the digital transformation of cement enterprises, and shared the pain points of cement industry. They further proposed the strategy of digital production and cement intelligent transformation to implement lean management.

The glass group gave an overview of float glass process and kiln management. Based on the needs of digital transformation, they analyzed the situation and quality control of float glass industry.

The ceramic group introduced the digital transformation and cost reduction of ceramic enterprises, including optimization of materials loading, manufacturing steps and energy consumption.

In the end, Dr. Mengna Hong, VP of POI-TECH and Bin Yan gave comments on their presentations, and Professor Panchao Yin of SCUT made a summary of the three-week internship.

Through this successful internship at POI-TECH, the students were exposed to a brand-new field on inorganic materials. They not only learned the production process and key equipment in cement, glass and ceramic industry, but also had a better understanding of digital transformation, big data modeling and applications in traditional manufacturing industries. This unique experience has made a profound impact on their future scientific research.