Professor Xiaohu Yao's research group (from South China University of Technology, School of Civil Engineering and Transportation) published an article in the title “A cavitation and dynamic void growth model for a general class of strain-softening amorphous materials” in the Journal of the Mechanics and Physics of Solids on May 19, 2020. The first author is Dr. Xiaochang Tang, the corresponding authors are Professor Xiaohu Yao and Professor Justin W. Wilkerson of Texas A&M University, and the co-author is Dr. Thao Nguyen. Dr. Tang is a graduate of SCUT's Development Class of Engineering Mechanics. The findings of the study demonstrate the benefits of the high-level compound talent training approach.

Metallic glass is created by rapidly supercooling a multi-component metal solution below the glass transition point. MG’s ultra-high specific strength, corrosion resistance, and wear resistance make it suitable for spacecraft structural materials and tank armor protections. When shrapnel strikes tank armor, the stress waves combine after internal reflection to generate a tensile stress zone, resulting in dynamic tensile failure, or said spallation. To meet the demands of armor protection, a systematic study is required to improve our understanding of metallic glass's dynamic mechanical properties and damage progression process.

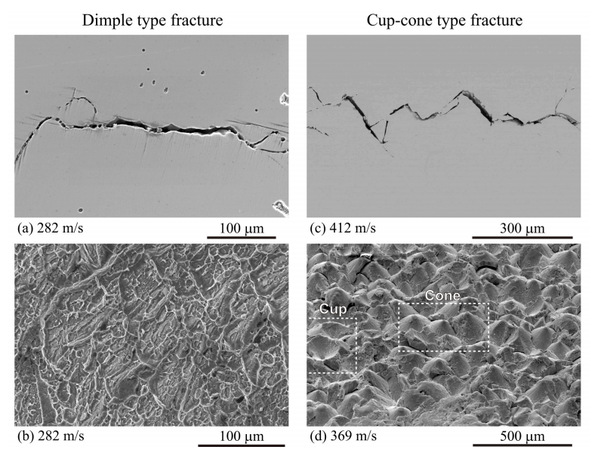

Fig. 1 Spallation morphology of MGs under planar impact

With the increase of impact velocity, the fracture morphology transits from dimple type to cup-cone type, termed as ductile-brittle transition. The spallation damage evolution process of metallic glass has its particularity. Traces of both ductile dimple coalescence and brittle shear band evolutions can be found on its spall surface. More specially, there is a unique conical structure uniformly distributed on the fracture surface, termed as cup-cone structure.

In the previous research, the research group has carried out quantitative statistics on the spallation surface morphology of metallic glass under different impact pressures through systematic experimental research, obtained many damage characteristics under micro scales, such as the vertex spacing, cone angle, and orientation of cup cone structure, and observed that the size of cup cone structure and vertex nucleation spacing decrease with the increase of impact pressure. The research results are different from the views held by previous researchers. It is considered that the difference of fracture surface morphology under different impact pressure may not come from the interaction between nucleation sources, but from the strain-softening behavior of metallic glass. It is speculated that the impact pressure is sufficient to soften the matrix, which is an important reason for the formation of cup-cone structure.

In this work, the research group constructed a model of amorphous plastic and dynamic void growth (APD theory) based on free volume evolution theory and dynamic void growth theory. The model can be used to describe the evolution of shear bands and voids, and then reproduce the fracture morphology transition in finite element methods simulations. The model uses the free volume theory to describe the plastic flow behavior of amorphous alloys. At the same time, the approximate function of material strength is used as a bridge to communicate the dynamic void growth theory, and then the effects of initial free volume softening effect and viscosity effect of metallic glass on spallation strength can be taken into account.

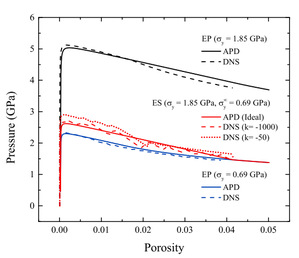

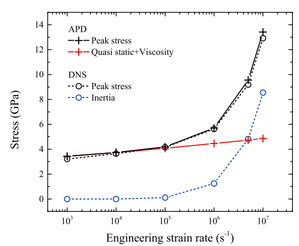

Fig. 2 (a) Pressure-porosity curve predicted by the ideal plastic model and strain-softening model. (b) APD theoretical prediction and DNS simulation results under different strain rates.

Previous studies on the void growth of strain-softening materials are very few, and mostly refer to the softening section of crystalline materials after strain hardening or the shorter softening section before polymer strain hardening. There is no study on the typical strain-softening behavior of metallic glass. This study points out that the strain softening effect caused by free volume evolution in metallic glass will significantly reduce the spallation strength and greatly accelerate the subsequent damage evolution process. It can be seen from Fig. 2 (a) that the spall strength predicted by the ideal plastic model is as high as 5 GPa, while less than 3 GPa is left after considering the strain-softening effect. Therefore, it is important to consider the strain-softening behavior of the matrix material in the constitutive model of spallation damage evolution. At the same time, direct numerical simulation (DNS) is used to verify the effectiveness of APD theory. It can be seen from Fig. 2 (b) that the peak stresses simulated by APD and DNS have high coincidence under different strain rates.

Through the combination of experiment, simulation, and theory, this series of work studies the spallation damage evolution behavior of metallic glass under dynamic impact loading, which provides a systematic understanding of the transformation process of spallation surface morphology of metallic glass under different impact pressures: At low speed, the strain-softening degree is insufficient and the conical shear band cannot be activated around the initial nucleation source. Therefore, the subsequent nucleation sources are still distributed along the plane perpendicular to the impact direction, and the morphology of the corresponding spallation surface is dominated by dimples. With the increase of impact velocity, the evolution of free volume becomes more and more significant. Finally, when approaching the elastic-plastic limit (HEL), the material has a significant strain-softening behavior. The conical shear zone is activated at the initial nucleation source (the apex of the cup cone structure). The subsequent nucleation sources continue to distribute along this path, nucleate, expand, penetrate and finally fracture in the form of voids, and the cup-cone structure begins to appear on the corresponding spallation surface. When the impact pressure exceeds HEL, the cup-cone structure begins to dominate the spallation surface morphology, and with the increase of impact pressure, the cup cone structure size and vertex spacing gradually decrease.

The research was supported by The National Science Fund for Distinguished Young Scholars (No. 11925203), the Doctoral Innovation Fund of South China University of Technology (2018), and the China Scholarship Council. At present, Professor Xiaohu Yao's research team of South China University of technology has jointly carried out a series of research work with Alamos National Key Laboratory, University of California Santa Barbara, Purdue University, University of Southern California, and Texas A&M University. Related works have been published in the Journal of the Mechanics and Physics of Solids, International Journal of Plasticity, Acta Materialia, Carbon, International Journal of Impact Engineering. Their research fields mainly involve the deformation, damage, and failure mechanism of amorphous alloys, high entropy alloys, silicon carbide ceramics, aviation transparent materials, polymer soft materials, and carbon fiber composites under extremely dynamic loadings.

Link: https://doi.org/10.1016/j.jmps.2020.104023