Mingxin Zhang

Metal-organic polyhedron (MOP), a large group of nanoscaled, cage-like molecular cluster defined by the coordination between metal ions and polydentate ligands, provide interesting candidates for use as NPs in the fabrication of star-like polymer nanocomposites.[6] In comparison with regular NPs, MOPs possess monodisperse, well-defined structures, and tunable surface properties, e.g. surface functional groups. However, poor mechanical performance and processability pose major barrier to their further use, especially in device fabrication. To solve these issues, MOPs have been hybridized with polymers via typical trial and error strategy for the possible synergistic effect from the inorganic components’ porosity and versatile functionalities, and the tunable mechanical and thermal properties of polymers. Nonetheless, the rational design of the composites is still beyond our capability mainly because of the lack of the knowledge of the hybrids’ structures across multiple length scales and the correlation between their performances and structures.

Recently, Prof. Panchao Yin’s group (South China Advanced Institute for Soft Matter Science and Technology) takes full use of the small angel X-ray and neutron scattering to verify the special morphology characterization that the polymer chains anchored surrounding around MOP surface are comparatively compact. Meanwhile, typical confined-extending surrounded by one entanglement area has been proposed. Then, this model is successfully used for dictating the counterintuitive thermal and rheological properties and prohibited solvent exchange properties of the nanocomposites. Finally, enlightened by the uncovered relationship between the basic structure and behavior of the MOP nanocomposites, a MOP-composited thermoplastic elastomer has been successfully obtained for the first time. This literature has been published on《Angew. Chem. Int. Ed.》.

Experiment design: The combination of living anionic polymerization and MOPs can provide an ideal nanocomposites system with well-defined and devisable structures for the investigation of structure-functionality relation. Herein, the so-called convergent approach is applied for the design and synthesis of hairy NPs. The obtained hairy NPs have been fully studied by scattering, imaging, and chromatographical techniques for their structures and morphologies in both solutions and bulk states. Meanwhile, the unique properties of polymer densely grafted and confined onto the surface of MOP has been probed via thermal and rheological analysis. Guided by the structure-property relation revealed in the nanocomposites, the first MOP thermoplastic elastomer has been obtained by designing the polymer components and its application as gas separation membrane has been domenstrated.

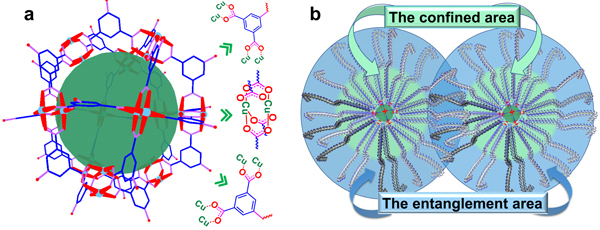

Figure 1. (a) Modelled structure of Cu cuboctahedron nanocage (MOP),hydrogen atoms and coordinated solvent are deleted and a deep-green background is used at the centre of MOP core for clarity; (b) Modelled structure of PS-MOP (24 polystyrene chains (the grey segment) are anchored onto the surface of one MOP core); the green and light blue regions refer to the confined area and entanglement area, respectively.

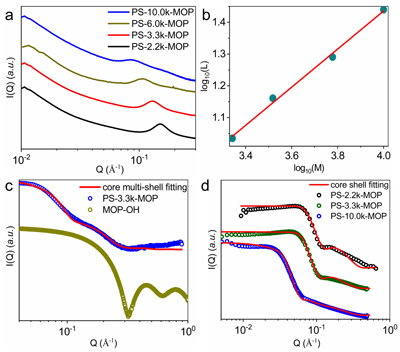

As powerful methods to probe the structure and morphology, SAXS and small angle neutron scattering (SANS) are used to study the structures of hairy NPs in solution or solid state. The sphere core structure can be confirmed with the help of SAXS that is more sensitive to heavy atom (in Figure 2c). On the other hand, the SANS (Figure 2d), a unique tool to study soft matter, is used to uncover the arm polymer morphology of hairy NPs in solutions. After combining those techniques, they have uncovered the micromorphology characterization of hairy NPs.

Figure 2. (a) The SAXS result from the solid PS-MOPs which reveals the distribution of PS-MOPs in bulk state; (b) The fitting relationship between L and M based on the solid SAXS result, the fitted equation is

SAXS measurements are conducted on their bulk samples to probe the average inter-particle distance (Figure 3a and 3b). They defined L as the dimension occupied by a single PS chain averagely (

Table 1. The calculated results from the solid SAXS

Sample ID | shell thickness /Å[a] | Rg in THF /Å[b] | |

PS-2.2k-MOP | 31.6 | 16.4 | |

PS-3.3k-MOP | 36.2 | 20.4 | |

PS-10.0k-MOP | 71.9 | 37.4 | |

[a] The data are from SANS fitting. [b] The value is the Rg of one free arm chain of PS-nk-MOP from a former report.

Considering all effects, the simple core-shell models is perfectly used to avoid overfitting for SANS (Figure 2d). The shell thicknesses are fitted from 3.16 nm (Mn= 2.2k) to 7.19 nm (Mn= 10.0k), which are close to the double of the ideal radius of gyration (Rg) of pure PS with the same Mn of the arm chain of hairy NPs in the good solvent (THF), respectively (Table 1). Meanwhile, the scattering length density (SLD) inside the hollow MOP core that remains as the solvent in synthesis deviates from that of pure deuterated solvent that is used to dissolve hairy MOPs. This phenomenon illuminate that the PS chains are densely packed and confined on the surface MOPs and the space of MOP surface is fully occupied by PS, which finally resist the penetration of outside solvent molecules.

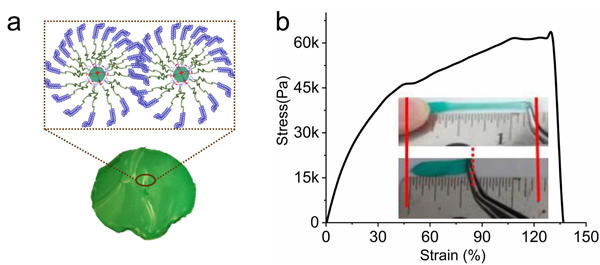

Figure 3. a) Modelled structure of PS-PI-MOP; d) The tensile curve and a visualized tensile test of PS-PI-MOP, the curve is smoothed for clarity.

After fully understanding the morphology characterization of hairy NP, the first MOP-composited thermoplastic elastomer (PS-PI-MOP) is successfully designed. As the aforementioned morphology characterization of hairy NPs, the PS chain segments entangle together and form the stiff glass domains; meanwhile, the long and flexible PI segments provide the nanocomposite with high reserve of entropy change, expressing good entropic elasticity and thermoplasticity. Therefore, being like typical thermoplastic elastomers (SBS), the stiff phases—PS and MOP, are embedded into the continuous PI phase and form the physical net-points to resist the deformation from the external forces.Finally, the elastomer shows good elasticity and desired gas-separation ability.

In sum, the author has fabricated the well-defined star nanocomposites with MOPs as cores and has systemically explored from morphologies to physical properties. Two main domains, the confined-extending area and the entanglement area, in the microstructure of hairy NPs have been verified from scattering measurements. After constructing the double layer micro-morphology model, they successfully illuminated the unique thermal and rheological behaviors. Finally, they developed the novel PS-PI-MOP(the first MOP-composited thermoplastic elastomer), which has good elasticity and desired gas-separation ability. This fundamental studies will accelerate the developments in the rational design of porous coordination framework with desired processabilities and mechanical/rheological/thermal performances.

This projection has been supported by the National Natural Science Foundation of China (No.51873067), Natural Science Foundation of Guangdong Province (No. 2018A030313503) and the Fundamental Research Funds for the Central Universities (No. 2018JQ04). The experiments are also support from China Spallation Neutron Source (CSNS) and Shanghai Synchrotron Radiation Facility (SSRF) for the access of SAXS (BL-16B),SANS and Multi-purpose neutron Reflectomer (MR) beamlines. The research performed in CG-2 (GP-SANS) at ORNL’s Spallation Neutron Source was sponsored by the Scientific User Facilities Division, Office of Basic Energy Sciences, U.S. Department of Energy and the synchrotron-based SAXS study carried out in 12-ID-B used resources of the Advanced Photon Source, a U.S. Department of Energy (DOE) Office of Science User Facility operated for the DOE Office of Science by Argonne National Laboratory under Contract No. DE-AC02-06CH11357. Last but not least, the authors are specially grateful to the selfless help from Dr. Weiyu Wang.

Mingxin Zhang Yuyan Lai Mu Li Tao Hong Weiyu Wang Haitao Yu Lengwan Li Qianjie Zhou Yubin Ke Xiaozhi Zhan Tao Zhu Caili Huang* Panchao Yin*

DOI:10.1002/anie.201909241

The literature URL: https://onlinelibrary.wiley.com/doi/abs/10.1002/ange.201909241

The representative of authors (from lift to right): Yuyan Lai; Qianjie Zhou; Mu Li; Mingxin Zhang; Haitao Yu; Panchao Yin.