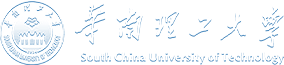

泡沫木材超级吸声材料制备技术

Key technologies for super sound absorbent of wood foam

在过去的数十年里,由于传统降噪保温材料经常对人体产生危害某些绝缘建筑材料对人的健康和环境的影响,引起了公众的极大关注,同时也希望有一种更健康的建筑材料替代品。建筑物消耗大量的能源用于如供暖、通风和空调服务。欧盟建筑的能耗约占欧盟年度总能耗的40%(欧盟委员会,2001),隔热系统已经成为优化建筑节能的一个重要工具。噪声污染是工业化国家日益关注的一个问题。世界卫生组织报告说(1995年),26%的欧洲居民暴露在超过65分贝的噪音水平下,根据世界卫生组织的标准,噪音水平的上限为世界卫生组织的标准是大约55dB。在连续的噪音暴露下,皮质醇水平在工作结束时,皮质醇水平达到早晨记录的水平,其结果是累积的疲劳和工作后的烦躁。此外,生活在较嘈杂环境中的儿童已被证明对压力的反应更差的反应,比生活在安静环境中的儿童更差。

Over the past several years, due to the often hazardous effects of certain insulation building materials, both to one’s health and to the environment, there has arisen a great public concern along with the desire for a healthier alternative to what is now being used as insulation building materials. Buildings consume a significant amount of energy for services such as heating, ventilating, and air conditioning. EU buildings consume about 40% of EUs total annual energy consumption (European Commission, 2001). Thermal insulation systems have emerged as a vital tool for the optimization of building energy conservation. Noise pollution is an increasing concern of industrialized nations.1,2 The World Health Organization reported (1995) that 26% of the European population in residential areas are exposed to noise levels of over 65 dB, given that the upper limit for noise level according to World Health Organization standards is about 55 dB. Under continuous noise exposure, cortisol levels at the end of the work shift reaches levels in the range of those recorded in the morning. The results are accumulated fatigue and post-work irritability.3 In addition, children who live in noisier environments have been shown to react more poorly to stressful situations than those living in a quiet environment.

图1 噪声控制机理与泡沫木材超级吸声材料大尺寸样板

众所周知,纸张、纸板以及纤维板绝大部分是以植物纤维为原料,通过湿法、干法等方式和化学助剂的作用下制备的纤维成形体材料,已广泛应用于人们生活中的多个领域。通常情况下纸张、纸板等造纸工业制品均为低定量(即超低密度)的纤维成形体材料,呈轻量化且薄型结构,在使用过程中给人一种轻松、清洁的感觉。与此同时,作为木材工业领域用的纤维板材料,其主要包括湿法纤维板和干法纤维板。湿法纤维板的制造主要来源于纸张的抄造工艺技术,利用纤维与纤维在脱水过程中以氢键等的作用下结合并成型,而干法纤维板是在湿法纤维板制造技术的基础上开发的,是对湿法纤维板成型工艺的改进与提高,主要克服湿法纤维板工艺过程中存在用水量大、污染严重、能耗大等问题。

As we all know, paper, cardboard and fibreboard are mostly made from plant fibres, prepared by wet and dry processes and chemical additives, and are widely used in many areas of life. Paper and cardboard products for the paper industry are usually low-weight (i.e. ultra-low density) fibre-forming materials with a lightweight and thin structure, which gives a relaxed and clean feeling during use. At the same time, fibreboard materials for the wood industry mainly consist of wet and dry fibreboard. The manufacture of wet fibreboard is mainly derived from the technology of paper copying, where fibres and fibres are combined and shaped by hydrogen bonding during the dehydration process, while dry fibreboard is developed on the basis of the wet fibreboard manufacturing technology, which is an improvement and enhancement of the wet fibreboard forming process, mainly to overcome the problems of high water consumption, pollution and energy consumption in the wet fibreboard process.

与不可再生的传统石化资源相比,自然界广泛存在林木、草本生物质资源(如木材,纤维素、草类等)是地球上最丰富的可持续利用的重要资源之一。仅天然树木而言,全世界有3万亿棵树(约人均420棵).

In comparison to conventional non-renewable petrochemical resources, readily available forest and herbaceous biomass resources (such as wood, cellulose, and grasses) rank among the planet's most plentiful, vital, and sustainable resources. Consider natural trees as an example. There are approximately 3 trillion of them worldwide (or 420 trees per person).

图1 丰富的森林资源

目前我国研究的低密度纤维成形体,其密度一般仍很高(≥200kg/m3)且厚度较低(≤50mm),而国外研制的密度低于100kg/m3的超低密度纤维成形体,但产品厚度仍偏低(≤30mm),应用范围窄且还没有出现作为特殊的功能性材料使用的报道。采用现有的热压成型技术或蒸汽喷射热压技术制造的材料还无法满足超低密度和更厚型的要求。而目前国内外则主要是通过添加化学发泡剂或采用高频热压法、微波热压法或喷蒸热压法、加工成型技术来制备这种低密度纤维成形体材料的,这种方法存在诸多的难题,如工艺与设备复杂、生产周期长、难控制、效率低、能耗大、生产成本高,且制备的产品厚度低等缺陷。

At present, China's research into low-density fibre-forming body, its density is generally still very high (≥ 200kg/m3) and low thickness (≤ 50mm), while foreign research and development of density below 100kg/m3 ultra-low density fibre-forming body, but the thickness of the product is still low (≤ 30mm), the application range is narrow and has not yet appeared as a special functional material use of the report. The existing thermoforming technology or steam injection thermoforming technology does not yet meet the requirements of ultra-low density and thicker shapes. At present, domestic and international are mainly through the addition of chemical foaming agent or the use of high-frequency hot pressing method, microwave hot pressing method or steam jet hot pressing method, processing and forming technology to prepare this low-density fibre into the body of the material, this method has many problems, such as complex processes and equipment, long production cycle, difficult to control, low efficiency, high energy consumption, high production costs, and the preparation of products with low thickness and other defects.

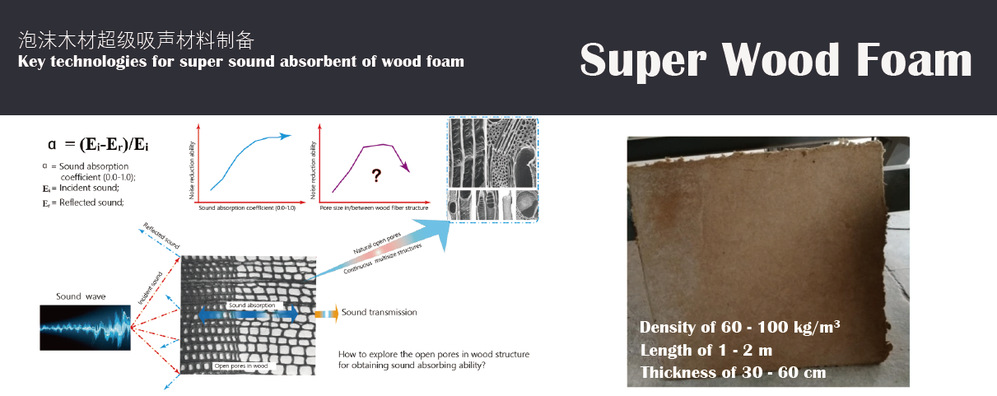

图2 普通木材与泡沫木材的吸声结构与性能

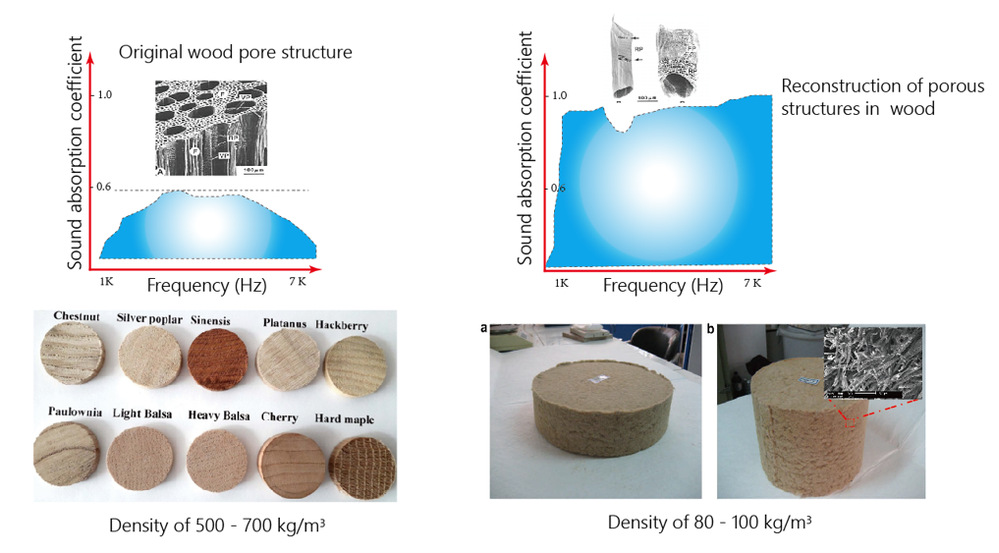

泡沫木材具有优良的隔热吸声性能,其导热系数可在0.04700 - 0.05600 kcal/mh℃,且具有在宽声频(250 - 7000 Hz)范围内很高的吸声系数值,吸声系数会随声频的增大而先快速增大、后缓慢降低再次增大至稳定的变化趋势,其降噪系数NRC可达0.7-0.9,平均吸声系数可达到0.4-0.7。制备该超低密度纤维功能成形体所需生产周期约为1.5 min (包括渗透时间1-30 s,透射时间1 s和保存时间为1 min),与聚乙烯泡沫塑料等的生产周期相当,是传统的热模压法生产周期的1/25 – 1/100,比喷蒸热压法生产周期还缩短近1/2,该成型新技术与装备具有操作更简单、投资成本低和能耗低等优点。制备的纤维功能成形体具有优良的缓冲动力学性能、隔热吸声性能及尺寸稳定性能好等,同时还具有良好的机械加工性能,产品易锯割,显自然色,质软且富有弹性,无任何甲醛等有毒气体释放,是一种真正意义上的绿色环保的新材料,具有非常看好的发展潜力和应用价值。

The results indicated that the materials have also good thermal-insulating and sound absorption properties. The thermal conductivity of the materials can vary from 0.04700 kcal/mh ℃to 0.05600 kcal/mh ℃. In addition, the materials have good sound absorption properties, exhibiting high sound absorption coefficients over a wide portion of the frequency range of interest from about 250 to 7000 Hz. The NRC (Noise Reduction Coefficients) calculated from the average sound absorption coefficient values of 125 Hz, 500 Hz, 1000 Hz and 2000 Hz of the BTAMs were about 0.7 - 0.9, and the average sound absorption coefficients were about 0.4 - 0.7. A moulded sample of the functional fibrous shaped body can be released from the former after total cycle time of 1.5 min, including transmission time of 1 s, penetration time of 10 - 30 s and holding time of 1 min, which was approximately the same as the total production time of moulded pulp or styrene foam, was 1/25 to traditional hot-pressing method and nearly 1/2 to the steam injection-hot pressing method. The new developed technology and equipment has advantages of easy operation, cost effective and low energy consumptions. The materials prepared in this work, has good cushioning properties as well as thermal insulation and sound absorption properties, and better dimensional stability. At the same time, the materials having no release of formaldehyde gas, are easily machined and soft and elastic, and can be also used as a new material for cushioning small electrical products.

图3 泡沫木材的吸声与保温性能及大幅面尺寸制造(厚度50mm, 密度80-100kg/m3)

图4 泡沫木材替代EPS等泡沫保温塑料使用

图5 泡沫木材的应用场景

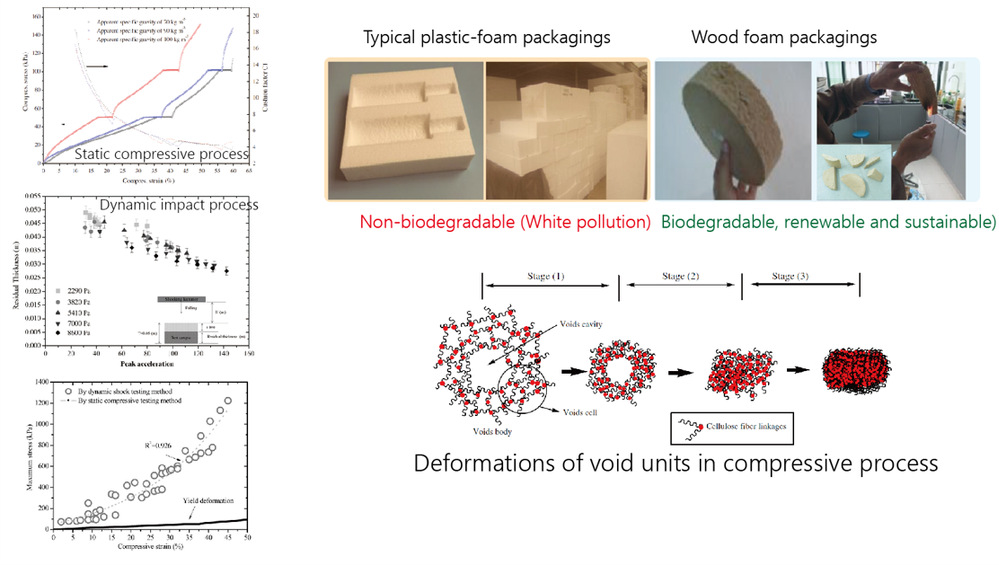

通过静态和动态缓冲动力学性能分析表明该成形体具有优良的缓冲动力学性能,其最小静态、动态缓冲系数可分别为3.57489和6.21667,且在静态压缩过程中通常会出现2次屈服效应,并通过建立理想的物理模型来揭示成形体在静态压缩过程中应力-应变量变化的机理。

The static and dynamic cushioning properties of the materials showed that the materials have excellent cushioning properties and energy absorbing abilities. The lowest static and dynamic cushion factor is respectively 3.57489 and 6.21667. Two yield deformation stages were generally observed in the compressive process, which were also further described by an ideal physical model. The results indicated that the materials have also good thermal-insulating and sound absorption properties.

图6 泡沫木材的缓冲动力学及替代泡沫塑料包装材料

新材料与技术属于我国战略性新兴产业发展规划的优先发展领域(生物制造、新材料与高端制造。预期制造的技术产品可在现代建筑(如宾馆、饭店、公共建筑、门板夹层材料、办公室隔板、活动建筑板房的房顶夹层材料、高层建筑影剧院、体育馆、歌舞厅、KTV房)应用,还可在家用空调产品中应用。

New materials and technologies belong to the priority development areas of China's strategic emerging industries development plan (bio-manufacturing, new materials and high-end manufacturing. The technology products expected to be manufactured can be applied in modern buildings (e.g. hotels, restaurants, public buildings, door sandwich materials, office partitions, roof sandwich materials for movable building panels, high-rise buildings theatres, stadiums, cabarets, KTV rooms) and also in household air-conditioning products.