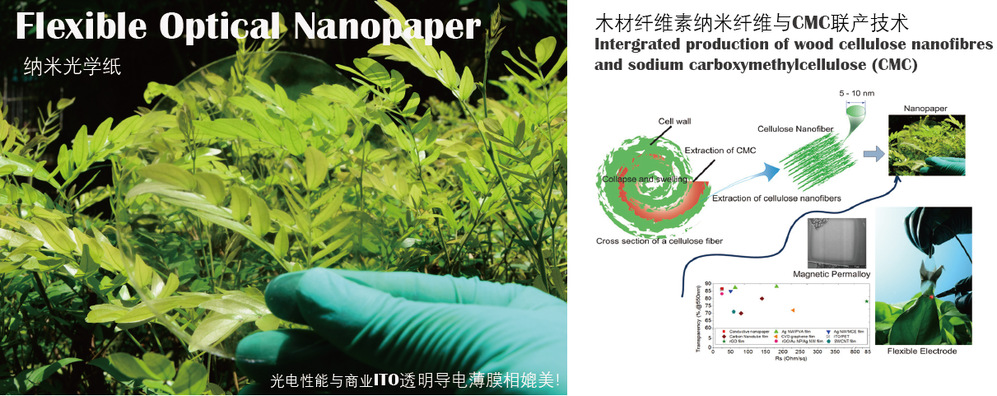

Congratulations Intergrated production of wood cellulose nanofibres and Sodium

Carboxymethylcellulose (CMC)

纤维素纳米纤维表现出优异的灵活性、可再生性、光学透射性、高杨氏模量的机械强度和低热膨胀系数,使其成为制造先进纳米材料的理想候选材料,包括纳米纸、气凝胶、水凝胶和柔性纸电子器件。典型的木质纤维中单个和聚集的纤维素纤维的直径约为5nm和20nm。

从宏观的木质纤维中提取纳米大小的纤维素纤维,可以获得其出色的机械和光学特性,用于各种应用。然而,由于纤维素被压制成纤维素聚集体而产生的强氢键和高度有序的结构,使得找到一种高产量和低能耗的方法将聚集体分解成单独的纳米纤维成为一项挑战。在过去的几十年里,已经成功地探索了许多方法,通过酶预处理、积极的机械过程、酸降解和化学修饰来分解木纤维。一个高产量和可持续的纤维素纳米纤维生产过程是非常理想的。

Cellulose nanofibers exhibit excellent flexibility, renewability, optical transmittance, mechanical strength with high Young’s modulus,and low coefficient of thermal expansion,making them ideal candidates for fabricating advanced nanomaterials including nanopaper, aerogel, hydrogel, and flexible paper electronics. However, processes to large scale extract nanoscale cellulose fibrils from macroscopic cellulose fibers pose significant challenges due to poor cost efficiency and high energy consumption. The diameters of individual and aggregated cellulose fibrils within a typical wood fiber are about 5 nm and 20 nm. Extracting the nanometer-sized cellulose fibrils from the macroscopic wood fibers provides access to their outstanding mechanical and optical properties for use in a variety of applications.However, the strong hydrogen bonding and highly ordered structure resulting from the compaction of fibrils into fibril aggregates make it a challenge to find a high yield and low energy consumption approach to disintegrate the aggregates into individual nanofibers. In past decades, many approaches have been successfully explored to disintegrate macroscopic wood fibers via enzyme pretreatment, aggressively mechanical processes, acid degradation and chemical modifications.but most of them suffer from either potential environmental toxicity. A high yield and sustainable process for cellulose nanofiber production is highly desired.

在这项工作中,本课题组与美国东北大学祝红丽教授团队、德国汉诺威莱布尼兹大学机械工程系Meriem Akin展示了通过一种新的部分溶解策略来制备纤维素纳米纤维的过程,该策略结合了友好和经济的化学预处理,包括碱化和乙酰氧钠化。

纤维素纤维是通过在无水NaOH/二甲基亚砜(DMSO)中处理来削弱氢键,从而削弱纤维素的晶体结构。其次,在无水ClCH2COONa/DMSO中对碱化的纤维素纤维进行醚化处理,将-CH2COONa基团引入纤维素链中。在天然纤维中部分形成水溶性的羧甲基纤维素钠(CMC),并在水洗过程中进一步从天然纤维中溶解,使纤维的细胞壁结构塌陷与分解。这种制备纤维素纳米纤维的新方法具有以下优点:(1)它是一种经济和生态友好的纤维素纳米纤维制备过程,在温和的条件下,纤维素纳米纤维的产量很高,达到56.5%;(2)除了纤维素纳米纤维之外,还共同生产了CMC这种重要的原料材料,因此整个过程几乎是零损失的。

In this work, we demonstrate a process to prepare cellulose nanofibers by a novel partial dissolution strategy which combines friendly and economical chemical pretreatments including basification and sodium acetoxylation. The basification of cellulose fibers is carried out by treating in anhydrous NaOH/dimethyl sulfoxide (DMSO) to weaken the hydrogen bonding and therefore weaken the crystal structure of cellulose. Secondly, sodium acetoxylation of the basified cellulose fibers in anhydrous ClCH2COONa/DMSO introduces –CH2COONa groups into the cellulose chains. The partial formation of water-soluble sodium carboxymethyl cellulose (CMC) in the natural fiber, and its further dissolution from the natural fiber collapses the cell wall of fiber during a water washing process. This new method for preparing cellulose nanofibers has the following advantages: (1) it is an economical and eco-friendly process of cellulose nanofiber preparation with high yield of cellulose nanofiber, 56.5 %, under mild conditions, and (2) CMC, an important feedstock material, is co-produced in addition to the cellulose nanofibers, therefore the whole procedure is zero loss.

图1 总体构思

我们开发了一种新颖的零损耗部分溶解策略,以获得56.5%的纤维素纳米纤维,其直径均匀为5-10纳米。这一策略也导致了CMC的形成和提取,CMC是一种重要的增稠剂和粘度调节剂,它促进了纤维素纤维的细胞壁的崩溃。当混合物用水清洗时,纤维素纳米纤维被进一步分离。得到的纳米纤维被用来生产具有高光学透明度、良好的机械强度、以及良好的可弯曲性和可折叠性的纳米纸。通过在湿的纳米纸片上直接沉积Ag NWs,我们能够制造出具有86.5%透明度和26.2Ω/sq片状电阻的坚固透明电极。此外,通过在纳米纸上溅射沉积一层电气合金薄膜,我们证明了该纳米纸适合作为薄膜磁性装置的平台,其低矫顽力和高饱和磁化可与基于二氧硅的磁性装置相媲美。所报道的纳米纸具有良好的表面光滑度、柔韧性和透明度,有望成为主要的可再生替代品,并将在未来几代柔性和可折叠的透明电子产品和磁电子学中继续发展。

We developed a novel zero loss partial dissolution strategy to yield 56.5% cellulose nanofibers with a uniform diameter of 5–10 nm. This strategy also results in the formation and extraction of CMC, an important thickener and viscosity modifier, which facilitates the collapse of the cell wall of cellulose fibers. The cellulose nanofibers are further separated when the mixture is washed with water. The obtained nanofibers are used to produce nanopaper with high optical transparency, good mechanical strength, and excellent bendability and foldability. By directly depositing Ag NWs onto the wet nanopaper sheet, we are able to fabricate robust transparent electrodes with 86.5% transparency and 26.2 Ω/sq sheet resistance. Furthermore, by sputter depositing a thin film of permalloy on the nanopaper, we demonstrated that the nanopaper is suitable as a platform for thin film magnetic devices exhibiting low coercivity and high saturation magnetization comparable to silicon dioxide-based magnetic devices. The reported nanopaper with excellent surface smoothness, flexibility, and transparency is promising to become a major renewable alternative that will continue to be developed in future generations of flexible and foldable transparent electronics and magnetoelectronics.

图2 工艺技术流程

图3 纤维制备化学结构

图4 纤维素纳米纤维结构与热稳定

图5 柔性纳米纸光学与力学

图6 柔性纳米纸电子的结构与光电性能

图7 纳米纸导电与柔性特征

我们在纳米纸平台上溅射沉积了5毫米×5毫米正方形的厚度为150nm的permalloy(Py:Ni81wt%Fe19wt%)薄膜。为了评估基于纳米纸的系统的磁性能,我们在二氧化硅和市面上的纸平台上制备了具有相同尺寸和涂层技术的Py:Ni81wt%Fe19wt%涂层。使用X射线衍射仪Bruker D8 Discover和钴阳极进行的X射线衍射测量,调查了过热合金涂层的结晶度。使用Debye-Scherrer、Williamson和Hall方程,X射线衍射数据表明,晶体大小和应变分别被确定为16.04 nm和5.14×10-4。

We sputter deposited 5mm×5mm square thin films of permalloy (Py:Ni81wt%Fe19wt%) of a thickness of 150 nm onto nanopaper platforms. In order to evaluate the magnetic performance of the nanopaper-based systems, we prepared Py:Ni81wt%Fe19wt% coatings with the same dimensions and coating technique on silicon dioxide and commercially available paper platforms. The crystallinity of the permalloy coating was investigated using an X-ray diffraction measurement conducted with the X-ray diffractometer Bruker D8 Discover and a cobalt anode. Using the Debye–Scherrer, Williamson, and Hall equations, the X-ray diffraction data indicated that the crystallite size and strain were determined to be 16.04 nm and 5.14 × 10–4, respectively.

图8 磁性纳米纸结构

对于快速切换的电气合金涂层,预计其矫顽力和饱和磁化率将分别达到最低和最高。与二氧化硅层相比,基于纳米纸的Py:Ni81wt%Fe19wt%薄膜表现出的低矫顽力和高饱和磁化可与基于二氧硅的磁性装置相媲美。这主要是由于其优越的表面质量(更细的孔隙率、平面度和更低的表面粗糙度)和与Py:Ni81wt%Fe19wt%更接近的机械性能。因此,纳米纸作为一种替代性的有机平台,对制造磁性和磁电子器件的适用性得到了证实。

For rapidly switching permalloy coatings, the coercivity and the saturation magnetization are anticipated to be lowest and highest, respectively. In comparison to the silicon dioxide layer, the nanopaper-based Py:Ni81wt%Fe19wt% thin films exhibit a low coercivity similarly to that of the silicon dioxide platform and a higher saturation magnetization than the commercial paper, mainly due to its superior surface quality (finer porosity, planarity, and lower surface roughness) and closer mechanical properties to Py:Ni81wt%Fe19wt%. Hence, the suitability of nanopaper, as an alternative organic platform, for the fabrication of magnetic and magnetoelectronic devices was proven.

图9 纳米纸的磁性特征