Advanced Sustainable Systems

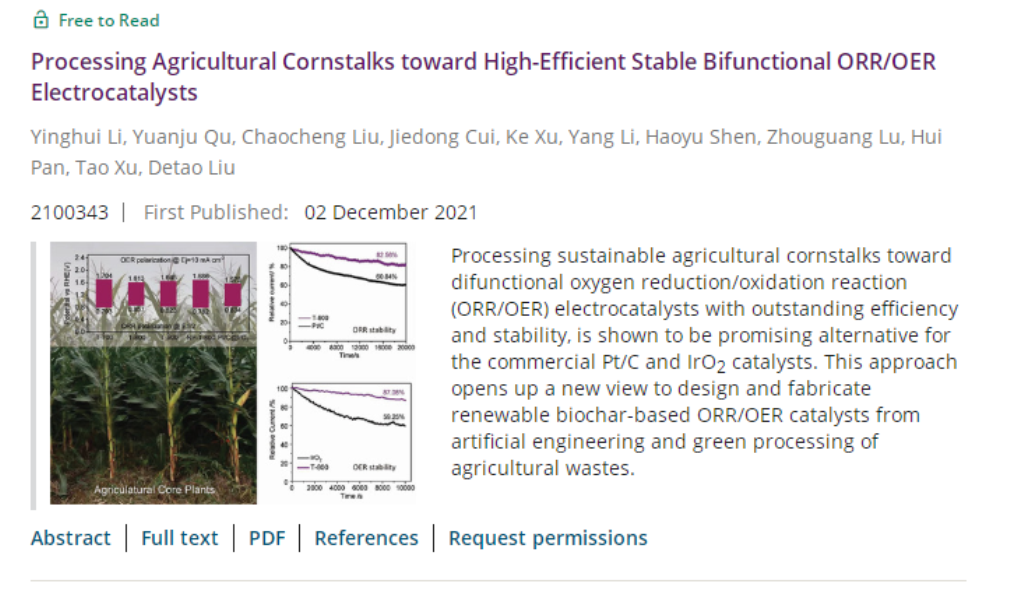

Processing Agricultural Cornstalks toward High-Efficient Stable Bifunctional ORR/OER Electrocatalysts

Yinghui Li, Yuanju Qu, Chaocheng Liu, Jiedong Cui, Ke Xu, Yang Li, Haoyu Shen, Zhouguang Lu, Hui Pan, Tao Xu, Detao Liu*

Y. Li, C. Liu, J. Cui, K. Xu, Y. Li, H. Shen, Prof. D. Liu

School of Light Industry and Engineering

South China University of Technology

Guangzhou 510640, P. R. China.

Prof. G. Lu

Department of Materials Science and Engineering

Shenzhen Key Laboratory of Interfacial Science and Engineering of Materials

Southern University of Science and Technology of China

Shenzhen 518055, P. R. China.

Y. Qu, Prof. H. Pan

Joint Key Laboratory of the Ministry of Education

Institute of Applied Physics and Materials Engineering

University of Macau

Macao SAR 999078, P. R. China.

Prof. T. Xu

Guangdong Provincial Key Laboratory of Building Energy Efficiency and Application Technologies

Academy of Building Energy Efficiency

School of Civil, Engineering, Guangzhou University

Guangzhou 510006, P. R. China.

#Y. Li and Y. Qu contributed to the work equally and should be regarded as co-first authors.

*Corresponding author: Detao Liu

E-mail: dtliu@scut.edu.cn

Advanced Sustainable Systems

DOI: 10.1002/adsu.202100343

可充电金属-空气电池、燃料电池等因其具有较高的理论比能(约1086 Wh/kg),且生产成本低,清洁环保、可再生等优势进行能源收集而受到全世界的广泛关注。一般而言,析氧反应(OER)和氧还原反应(ORR)是阴极材料的两个关键反应,对创新电化学能源技术发挥重要的作用。而如今,贵金属Pt基催化剂和Ir/Ru基催化剂因其优异的电催化活性,被认为是目前最理想的商用ORR/HER、OER电催化剂。然而,它们还存在重要的不足:如成本昂贵、原材料稀缺、稳定性差等因素严重制约了其大规模化应用,促使人们探索潜在的替代品成为当前国际社会亟需解决的迫切问题。广泛存在的碳质及其衍生混合材料(如石墨烯、碳纳米管和聚吡咯等)具有良好的电子导电性、良好的催化活性和高度暴露的活性位点,对其开展协同增强制备电催化剂被证实为最有前途的发展策略,但同样仍存在成本高、加工复杂且不可持续,难以进一步规模化生产。而自然界生物质材料(如木材或农业废弃物等)拥有许多显著优势,如天然的多级孔结构、来源极为广泛、含碳量高且极低成本,被认为是制备电催化剂极具潜力的选择,已有较多重要的研究报道,但对于如何利用农田广泛废弃且易造成二次环境污染的农业废弃物,以制备高性能、高稳定ORR/OER双功能电催化剂以替代昂贵的贵金属材料,显然是目前一个极具研究和商业价值的重大课题。

华南理工大学刘德桃课题组联合南方科技大学卢周广、澳门大学潘辉、广州大学徐涛课题组合作提出了一种两步法和ZnCl2造孔的策略,并将农业废弃玉米秸秆成功制备了高稳定、高性能的双功能ORR/OER电催化剂,充分利用ZnCl2造孔及其协同分散效应,解决了过渡金属Co, Fe在高温碳化过程中易聚集导致活性不足的难题,并通过过渡金属Co, Fe和非金属元素B, N的协同互补策略,赋予其与商业贵金属Pt基、IrO2基催化剂相当的ORR/OER双功能电催化活性,且拥有更高的稳定性和更低的生产成本。论文还通过DFT法进行了理论计算进一步论证本项目实施策略的可行性和科学性。该新技术的开发对于探索农业生物质废弃物制备高价值的双功能电催化级及其它催化材料具有指导和借鉴意义。

Main Contents:

Bifunctional oxygen reduction/oxidation reaction (ORR/OER) electrocatalysts derived from biomass are one of the most valuable materials in terms of sustainability, ecological economy and industrial manufacturing, and are emerging as a desired alternative to the commercial Pt/C and IrO2 catalysts. This work demonstrates the processing of agricultural cornstalk waste of cornstalks into stable bifunctional ORR/OER catalysts with high-performance by a simple and costeffective strategy. Rich hydrophilic active groups (e.g., hydroxyl groups) in the hierarchical porous structures of the native cornstalks enable the sufficient facile combination with transition metals (e.g., Co, Fe, Zn) and heteroatoms (e.g., B, N) from soluble Co(NO3)2, ZnCl2, H3BO3, NH4Cl in a hydrothermal reaction. The pyrolytic evaporation of Zn2+ in a high-temperature carbonization process facilitates the generation of abundant micropores and mesopores to increase specific surface areas (941.44 m2 g−1) and also hinders aggregation between neighboring transition metals. The synergistic effects of N, B, Fe and Co doping in hierarchical

porous biochar-structures contributes to outstanding bifunctional ORR/OER activities and working stabilities, outperforming commercial Pt/C and IrO2 catalysts. Computational results further verify the valuable synergistic contributions based on density-functional theory (DFT). This approach opens up a new possibility for the fabrication of bifunctional biochar-based ORR/OER catalysts from artificial engineering and green processing for sustainable agricultural wastes.

It was reported by X-MOL Media by Jan 18, 2022.

Please visit: https://www.x-mol.com/news/743981

The MaterialsViews reported it in the Biomedicine Section by Dec 29, 2021.

Please visit: https://mp.weixin.qq.com/s/kCWbOl-ir33bVxzM9WwYeg